I have top quality replicas of all brands you want, cheapest price, best quality 1:1 replicas, please contact me for more information

Contact Us:【whastapp : +8615779516951】 | 【telegram : @Mia399】 | 【instagram : huajuju111】

Scan the QR code to contact me

Bag

shoe

watch

Counter display

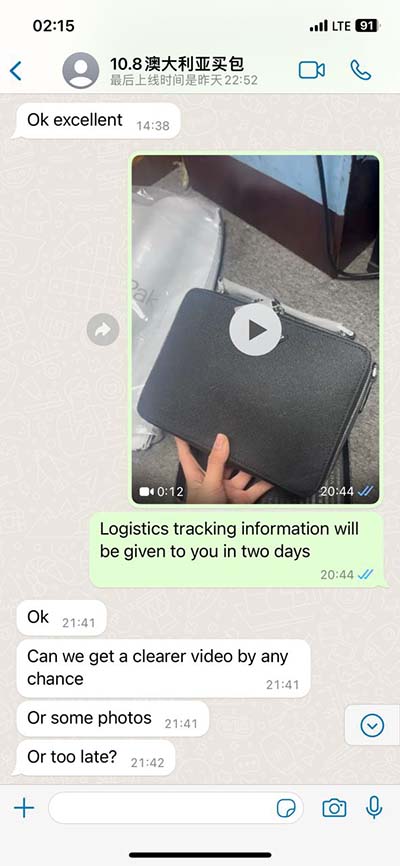

Customer feedback

Shipping