metallization process in ic fabrication Metallization characterization tests are determined by: (1) properties of metal thin films, (2) metallization requirements, (3) integrated circuit processing, and (4) long term stress. In this blog post, we have explored the essential components that move during CNC machining. From the spindle that rotates the cutting tool to the axis drives that control machine movement, .

0 · wafer preparation in ic fabrication

1 · wafer backside metallization

2 · metallization in semiconductor manufacturing

3 · manufacturing process of monolithic ics

4 · ic fabrication steps pdf

5 · ic fabrication process pdf

6 · explain the terminology for metallization

7 · backside metallization process

When farmhouse style first hit the scene we saw nothing but bright white home exteriors with wood and black accents. Now, farmhouse style has been around for a while and evolved to include these gorgeous dark exteriors, still .

Based on the types of applications there are three types of Metallization Process namely. 1. Gate metallization: The metallization which connects a base (in bipolar transistors) or gate (in MOSFETs) to the neighbouring two regions is called .After all semiconductor fabrication steps of a device or of an integrated circuit are completed, it becomes necessary to provide metallic interconnections for the integrated circuit and for .Figure 10.1 depicts the metallization scheme of a MOSFET. The primary metallization applications can be divided into three categories: gate, contact, and interconnection. Polysilicon and silicide .

Learn about the metallization process, which is the final step in the wafer processing sequence for IC fabrication. Find out the advantages and limitations of aluminium, gold, and other metals used for metallization, and .

Metallization characterization tests are determined by: (1) properties of metal thin films, (2) metallization requirements, (3) integrated circuit processing, and (4) long term stress.part i: metallization - overview, concerns, and advanced technology •manufacturing and technology requirements for submicron multilevel metal 3 t.e. seidel •self-aligned, metal .Learn about the process of metallization in silicon device manufacturing, which involves depositing metal layers on the wafer to form conductive pathways. Find out the common .

Metallization is applied either by evaporation or sputtering. Since all of these processes are only to be applied to specifically controlled areas, “masks” are used to expose only selected areas .In e-beam evaporation, an electron beam is aimed at the source material causing local heating and evaporation. Choice of evaporation method typically relates to the phase transition .Based on the types of applications there are three types of Metallization Process namely. 1. Gate metallization: The metallization which connects a base (in bipolar transistors) or gate (in MOSFETs) to the neighbouring two regions is called gate metallization. 2. Contact Metallization:After all semiconductor fabrication steps of a device or of an integrated circuit are completed, it becomes necessary to provide metallic interconnections for the integrated circuit and for external connections to both the device and to the IC. Etching is the process of selective removal of regions of a semiconductor, metal, or silicon dioxide.

Figure 10.1 depicts the metallization scheme of a MOSFET. The primary metallization applications can be divided into three categories: gate, contact, and interconnection. Polysilicon and silicide are frequently used in gates and interconnects in MOS devices.

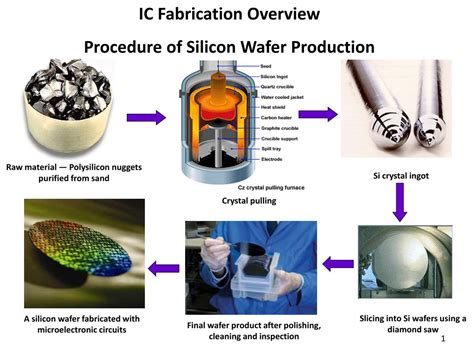

wafer preparation in ic fabrication

In this final episode, we will introduce the process of metallization which connects semiconductor devices using metals such as aluminum and copper. Metallization is the process by which the components of IC’s are interconnected by aluminium conductor. This process produces a thin-film metal layer that will serve as the required conductor pattern for the interconnection of the various components on the chip.

cooker junction box uk

Metallization characterization tests are determined by: (1) properties of metal thin films, (2) metallization requirements, (3) integrated circuit processing, and (4) long term stress.part i: metallization - overview, concerns, and advanced technology •manufacturing and technology requirements for submicron multilevel metal 3 t.e. seidel •self-aligned, metal-masked dry etch processing of iii-v electronic and photonic devices 19 s.j. pearton, a. katz, a. feingold, f. ren, t.r. fullowan, j.r. lothian, and c.r. abernathyAfter devices have been fabricated in the silicon substrate, connections must be made to link the circuits together. This process is called metallization. Metal layers are deposited on the wafer to form conductive pathways.

Metallization is applied either by evaporation or sputtering. Since all of these processes are only to be applied to specifically controlled areas, “masks” are used to expose only selected areas to difusion, ion implantation, or etchants. The patterning is accomplished by photolithography. A photoresist is applied to the surface.In e-beam evaporation, an electron beam is aimed at the source material causing local heating and evaporation. Choice of evaporation method typically relates to the phase transition properties of that material (for example, aluminum is quite difficult to evaporate using resistive heating).Based on the types of applications there are three types of Metallization Process namely. 1. Gate metallization: The metallization which connects a base (in bipolar transistors) or gate (in MOSFETs) to the neighbouring two regions is called gate metallization. 2. Contact Metallization:

wafer backside metallization

After all semiconductor fabrication steps of a device or of an integrated circuit are completed, it becomes necessary to provide metallic interconnections for the integrated circuit and for external connections to both the device and to the IC. Etching is the process of selective removal of regions of a semiconductor, metal, or silicon dioxide.Figure 10.1 depicts the metallization scheme of a MOSFET. The primary metallization applications can be divided into three categories: gate, contact, and interconnection. Polysilicon and silicide are frequently used in gates and interconnects in MOS devices.

In this final episode, we will introduce the process of metallization which connects semiconductor devices using metals such as aluminum and copper. Metallization is the process by which the components of IC’s are interconnected by aluminium conductor. This process produces a thin-film metal layer that will serve as the required conductor pattern for the interconnection of the various components on the chip.

Metallization characterization tests are determined by: (1) properties of metal thin films, (2) metallization requirements, (3) integrated circuit processing, and (4) long term stress.

part i: metallization - overview, concerns, and advanced technology •manufacturing and technology requirements for submicron multilevel metal 3 t.e. seidel •self-aligned, metal-masked dry etch processing of iii-v electronic and photonic devices 19 s.j. pearton, a. katz, a. feingold, f. ren, t.r. fullowan, j.r. lothian, and c.r. abernathyAfter devices have been fabricated in the silicon substrate, connections must be made to link the circuits together. This process is called metallization. Metal layers are deposited on the wafer to form conductive pathways.

Metallization is applied either by evaporation or sputtering. Since all of these processes are only to be applied to specifically controlled areas, “masks” are used to expose only selected areas to difusion, ion implantation, or etchants. The patterning is accomplished by photolithography. A photoresist is applied to the surface.

metallization in semiconductor manufacturing

control panel vs junction box

convert to sheet metal inventor

Choosing a perfect type of hammer for metalsmithing or jewelry work is rarely as simple as picking up the one closest to you. Different types of hammers have different uses and each style is perfectly suited for its intended use.

metallization process in ic fabrication|backside metallization process