sheet metal processes Sheet metal processing is a vast concept, covering several machining operations done to metal sheets. Since the topic is too broad, most people think the overall process only boils down to a single function. However, . During the early 20th century, metal became a popular material for tool storage. This type of toolbox could be mass-produced, so it's easy to find vintage metal tool boxes in a number of styles. The simplest examples featured a metal box with a hinged lid and a clasp to hold the lid closed.

0 · various sheet metal processes

1 · types of sheet metal process

2 · sheet metal working process pdf

3 · sheet metal processes pdf

4 · sheet metal process in manufacturing

5 · sheet metal operations with diagrams

6 · sheet metal forming process pdf

7 · sheet metal fabrication pdf

Boxplots are graphs that tell you how your data’s values are spread out. Here’s how to read a boxplot and even create your own.

Also known as sheet metal fabrication, sheet metal forming uses metal sheets to make various products and components. The metal sheets are formed and cut into the necessary shape and size via many different .

The family of manufacturing processes used to create sheet metal components encompasses a diverse range of techniques, each tailored to achieve specific shapes, sizes, and features with precision and efficiency.

Sheet metal processing is a vast concept, covering several machining operations done to metal sheets. Since the topic is too broad, most people think the overall process only boils down to a single function. However, .

Sheet metal manufacturing is the process of creating sheet metal parts by cutting, bending, and forming thin metal sheets into specific shapes and sizes. The process typically uses coating, cutting, bending, and assembly .

Sheet metal fabrication is the process of forming metal sheets to the desired shape using different manufacturing methods. The completion of a product usually comprises of many steps – from cutting and bending to .

Learn how to effectively design sheet metal parts. This guide starts with the basics and moves toward design best practices and advice on material selection, finishings and fastenings, with a focus on two sheet metal fabrication .The sheet metal fabrication process is an intricate journey from raw metal to a finished product. It involves various steps, ensuring the final product meets specific standards and functions. In . The art and science of sheet metal fabrication involve a series of meticulous processes, from designing and cutting to bending and welding. This article unpacks the top ten technological processes, guiding you through each .Sheet metal processing, in essence, is an umbrella term encapsulating a wide array of techniques employed to manipulate and transform flat sheets of various metals into specific shapes and forms. Why Sheet Metal Processing is .

Sheet metal expanding is a specialized process within sheet metal forming that involves stretching the metal to create a mesh-like pattern. This technique enhances the flexibility and strength of the sheet metal, making it suitable for various applications, including filtration, screening, and architectural details.Chap 2 , sheet metal – p. 1 Sheet Metal Forming Processes • involves workpieces with a high ratio of surface area to thickness • plates, thickness > ¼ inch • sheets, thickness ≤ ¼ inch • typical items produced by sheet-metal forming processes: metal desks appliance bodies . hubcaps aircraft panels . beverage cans car bodies Precision sheet metal fabrication is a popular technique used to shape raw materials. Thanks to the advanced technology, this technique ensures that every component meets exact specifications. Today, Fischer ASIA will discuss the various processes involved and highlight the advantages of precision fabrication.

8. SHEARING • It is a process of cutting a straight line across a strip, sheet • Metal is placed between upper punch & lower die. • Pressure is applied, plastic deformation takes place. • As the pressure is continued, the fracture or crack start at the cutting edge of the punch • As the punch descends further, the small fractures meet & the metal is then sheared. The document discusses various sheet metal processes including shearing, bending, drawing, and special forming processes. It provides details on: - Common shearing operations like punching, blanking, and notching used to cut sheet metal. - Forming processes like bending, stretching, and drawing that cause shape changes without cracking or . 5. Sheet Metal Processing The raw material for sheet metal manufacturing processes is the output of the rolling process. Typically, sheets of metal are sold as flat, rectangular sheets of standard size. If the sheets are thin and very long, they may be in the form of rolls. Therefore the first step in any sheet metal process is to cut the correct shape and . By an engineer with decades of practical manufacturing experience, this book is a complete modern guide to sheet metal forming processes and die design – still the most commonly used methodology for the mass-production manufacture of aircraft, automobiles, and complex high-precision parts. It illustrates several different approaches to this .

Bending is a fundamental sheet metal forming process that transforms 2D flat parts into 3D components with precise angles and contours. This operation is primarily executed using a press brake in conjunction with specialized bending dies. The process involves applying controlled force to deform the metal along a linear axis, creating permanent .

sheet metal santa rosa

Modern industrial processes rely heavily on sheet metal forming techniques, which allow flat metal sheets to be transformed into intricate three-dimensional structures. To deform and manipulate sheet metal into desired forms, sizes, and configurations, these procedures include the use of a variety of techniques, tools, and machinery.

It is a sheet metal process done to the edge of the sheet, whether creating a 90-degree angle and a T-shaped corner in the sheet or making the sheet’s edge thinner by making it thinner as it crosses over itself. Conclusion. Sheet metal processing is a vital part of the metal machining industry. Though it might seem simple, the work has high .Forming sheet metal. During the fabrication process, the sheet metal is usually first punched and cut in different ways and then followed by forming processes to make a nearly finished and realized product. Entire product chassis can be made in this way. Not only is forming metal convenient, it also adds strength and stiffness to an assembly.

various sheet metal processes

Curling is a sheet metal forming process that’s used to smooth out the otherwise sharp and rugged edges of sheet metal. Sheet metal often contains sharp edges with “burrs” after it’s initially produced. Curling is a forming process that involves de-burring sheet metal to produce smooth edges. #2) Bending. Another common sheet metal . Many processes are utilized to form parts from sheet metal, including laser cutting, plasma cutting, and sheet metal bending. This article will explore in detail what materials can be formed into sheet metal, sheet metal geometries, the most common sheet metal part-forming processes, and their applications.Galaxy offers sheet metal fabrication services since 1989, with a comprehensive range of in-house sheet metal work services including: Prototyping, Laser Cutting, Metal Bending, CNC Punching & Forming, CNC Machining, Welding, a full Powder Coating plant, Assembly, all .

Sheet metal means thin piece of metal. Sheet metals has large variety of applications in industries.It is used in1. Decoration2. Automobile industries3. Aero.The metal-forming process involves cutting and stretching a sheet of metal through perforating scissors, creating a structurally advantageous diamond-shaped mesh. This process is commonly used for manufacturing fences, catwalks, platforms, and grating, resulting in self-draining, strong products that support weight. Sheet metal curling is the process of adding circular, hollow rolls to sheet metal edges. Most curling processes occur in three stages; the first two stages create the curves for the curl, while the third stage closes up the curl. . Sheet metal working involves cutting, bending, drawing, and other forming operations to shape metal sheets. The processes include shearing, blanking, and punching, with various tools like punches and dies. Clearance, punch and die sizes, angular clearance, and stripper usage are crucial factors in achieving precise cuts. Fine blanking requires special .

The sheet metal powder coating process involves several key steps to ensure a successful and durable coating. Here is an overview of our typical processes involved: Pre-treatment Stage; The sheet metal surface must be thoroughly cleaned and prepared before powder coating. This involves removing any dirt, oil, rust, or existing coatings. This process is highly efficient and cost-effective, making it the preferred choice for producing long lengths of sheet metal with consistent profiles. Additionally, roll forming can handle various metals such as steel, aluminum, copper, and more. When it comes to manufacturing, sheet metal forming is a game-changer. Let’s explore some of key advantages of sheet metal forming process and some challenges one faces during the process. Benefits: High production rates allow meeting tight deadlines and satisfying customers. Minimal material waste from precise cutting and forming means cost .

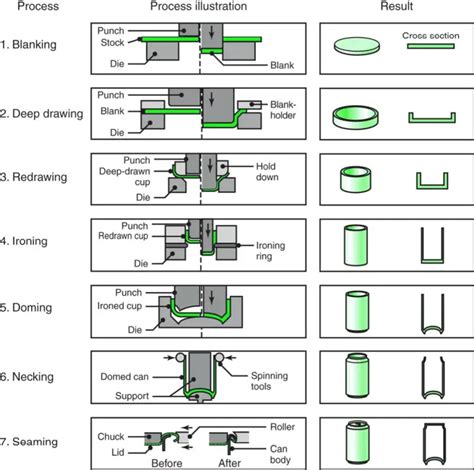

This chapter discusses sheet metal forming processes and equipment. It covers topics like shearing, bending, deep drawing, and other specialized forming techniques. Shearing is used to cut sheet metal blanks from larger sheets. Process parameters like punch and die shape, clearance, and speed affect shearing quality and forces.Sheet metal refers to metal that has a high surface area to volume ratio. Sheet metal work stock, used for sheet metal processes, is usually formed by rolling and comes in coils. A distinction needs to be made between sheet metal and plate metal. Sheet metal is 1/4 inch or less in thickness, while plate is over 1/4 inch in thickness.Sheet Metal Stamping Stamping presses and stamping dies are tools used to produce high volume sheet metal parts. The press provides the force to close the stamping dies where they shape and cut the sheet metal into finished parts. Production stamping is generally performed using sheet metal materials .020” to .080” thick, but the process

Reliable and durable sheet metal assemblies rely heavily on sheet metal parts fabricated with precision and efficiency in mind. Streamlining the process of sheet metal assembly, where accuracy and repeatability foster the fabrication of intricate and complex sheet metal components, is essential when serving leading manufacturers in today’s most important . It’s a process that cuts sheet metal into specific shapes and sizes. This technique requires applying heavy force to the metal, resulting in a clean, straight fracture. Metal shearing is typically used to produce precise cuts quickly and efficiently during sheet metal fabrication. The purpose of shearing metal is to create clean edges on .

types of sheet metal process

sheet metal working process pdf

Sheet metal screws are a special type of fastener designed specifically for metal sheets, utilizing the interplay of internal and external threads to secure sheet metal. These fasteners feature unique designs and characteristics that allow them to effectively generate sufficient bite force on metal sheets, achieving secure fastening.

sheet metal processes|sheet metal working process pdf