25 sheet metal bend radius Use Xometry reference tables for sheet and aluminium to find out which bend radius is the most suitable for your sheet metal projects What is a Wood Blank Cover? A wood blank cover is a flat piece of wood typically used to seal a junction box. These covers serve multiple purposes beyond aesthetics. First and foremost, they provide a layer of protection for electrical systems against .

0 · sheet metal bend radius guide

1 · sheet metal bend radius formula

2 · sheet metal bend radius calculator

3 · sheet metal bend deduction chart

4 · maximum thickness sheet metal bending

5 · how to calculate bend radius

6 · bend radius sheet metal chart

7 · bend radius definition sheet metal

$189.75

sheet metal bend radius guide

Use Xometry reference tables for sheet and aluminium to find out which bend radius is the most suitable for your sheet metal projects

sheet metal bend radius formula

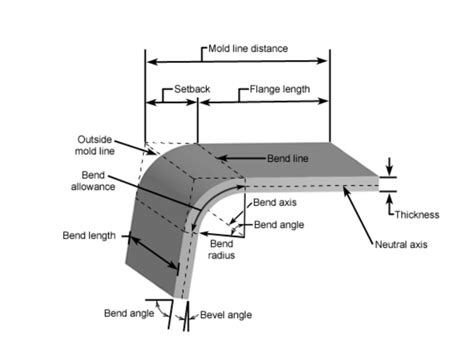

The bend radii listed are standard minimum if manufacturing for aircraft and aerospace applications. Since commercial sheet metal bending can be done with less concern for . The sheet metal bending radius is a critical value in sheet metal drawing that can be difficult to determine during the actual processing. This radius is dependent on the material thickness, the pressure of the press brake .

The tables below show bend radii and minimum bend sizes for materials and tooling combinations stocked by Protocase. We go beyond the general rules of sheet metal bending, as our . Just a few are the forming method (air forming, bottoming, or coining), the type of bend (sharp, radius, or profound radius bends), the tooling you are using, and the multibreakage of the workpiece during large-radius . Medium-carbon steels and some structural steels including 15, 20, Q235, Q235A, and 15F require a slightly larger minimum bend radius of 0.5t. Higher-carbon steels and higher-strength structural steels such as 25, 30, and .

Your best bet when designing formed parts is to use the industry standard bend radius of 0.030”. This measurement ensures consistent, high-quality parts with solid structural integrity. We use 0.030" for all material .

Sheet Metal Bend Radius Guidelines Here are a few key concepts to know about designing for sheet metal Brackets, covers, cabinets, chassis, electrical enclosures. We recommend a minimum bend radius of 1t for all sheet metal parts. Thus the smallest radius of any bend in a sheet should be at least equal to the thickness of the sheet. For example, if the thickness of the sheet is 1 mm, .

sheet metal bend radius calculator

sheet metal bend deduction chart

electrical metal pull boxes

It is most economical to use a single bend radius throughout the design, but if necessary, you can utilize multiple radii. Use this document to choose values that are both manufacturable and meet your needs.

Use Xometry reference tables for sheet and aluminium to find out which bend radius is the most suitable for your sheet metal projects

The bend radii listed are standard minimum if manufacturing for aircraft and aerospace applications. Since commercial sheet metal bending can be done with less concern for stresses caused during forming operation, the radius can be near zero for thin sheet metal. The sheet metal bending radius is a critical value in sheet metal drawing that can be difficult to determine during the actual processing. This radius is dependent on the material thickness, the pressure of the press brake machine, and the width of .

The tables below show bend radii and minimum bend sizes for materials and tooling combinations stocked by Protocase. We go beyond the general rules of sheet metal bending, as our customers want tight bend radii for sheet metal parts. It is possible to choose other bends if you require, but additional lead time and tooling charges may apply. Just a few are the forming method (air forming, bottoming, or coining), the type of bend (sharp, radius, or profound radius bends), the tooling you are using, and the multibreakage of the workpiece during large-radius bending.

Medium-carbon steels and some structural steels including 15, 20, Q235, Q235A, and 15F require a slightly larger minimum bend radius of 0.5t. Higher-carbon steels and higher-strength structural steels such as 25, 30, and Q255 necessitate a minimum bend radius of 0.6t due to their reduced ductility. Your best bet when designing formed parts is to use the industry standard bend radius of 0.030”. This measurement ensures consistent, high-quality parts with solid structural integrity. We use 0.030" for all material thicknesses up to 0.125" (⅛") and increase the bend radius for thicker materials.Sheet Metal Bend Radius Guidelines Here are a few key concepts to know about designing for sheet metal Brackets, covers, cabinets, chassis, electrical enclosures.

We recommend a minimum bend radius of 1t for all sheet metal parts. Thus the smallest radius of any bend in a sheet should be at least equal to the thickness of the sheet. For example, if the thickness of the sheet is 1 mm, the minimum bend radius should be 1 mm.It is most economical to use a single bend radius throughout the design, but if necessary, you can utilize multiple radii. Use this document to choose values that are both manufacturable and meet your needs. Use Xometry reference tables for sheet and aluminium to find out which bend radius is the most suitable for your sheet metal projects

The bend radii listed are standard minimum if manufacturing for aircraft and aerospace applications. Since commercial sheet metal bending can be done with less concern for stresses caused during forming operation, the radius can be near zero for thin sheet metal. The sheet metal bending radius is a critical value in sheet metal drawing that can be difficult to determine during the actual processing. This radius is dependent on the material thickness, the pressure of the press brake machine, and the width of .The tables below show bend radii and minimum bend sizes for materials and tooling combinations stocked by Protocase. We go beyond the general rules of sheet metal bending, as our customers want tight bend radii for sheet metal parts. It is possible to choose other bends if you require, but additional lead time and tooling charges may apply.

Just a few are the forming method (air forming, bottoming, or coining), the type of bend (sharp, radius, or profound radius bends), the tooling you are using, and the multibreakage of the workpiece during large-radius bending.

Medium-carbon steels and some structural steels including 15, 20, Q235, Q235A, and 15F require a slightly larger minimum bend radius of 0.5t. Higher-carbon steels and higher-strength structural steels such as 25, 30, and Q255 necessitate a minimum bend radius of 0.6t due to their reduced ductility.

Your best bet when designing formed parts is to use the industry standard bend radius of 0.030”. This measurement ensures consistent, high-quality parts with solid structural integrity. We use 0.030" for all material thicknesses up to 0.125" (⅛") and increase the bend radius for thicker materials.Sheet Metal Bend Radius Guidelines Here are a few key concepts to know about designing for sheet metal Brackets, covers, cabinets, chassis, electrical enclosures.

maximum thickness sheet metal bending

how to calculate bend radius

$1,558.95

25 sheet metal bend radius|sheet metal bend radius guide