cnc machine coding language For anyone wondering whether or not they should control their CNC machines with hand-written code or with CAM-generated code, the first thing to do is to learn all about that coding language. Understanding what it is, how . ACSMA provides a voice for union sheet metal and air conditioning contractors in Los Angeles and Kern County. ACSMA enhances the business and profitability of its members through a wide range of services.

0 · manual cnc programming for beginners

1 · list of cnc g codes

2 · different types of cnc programming

3 · cnc turning g code list

4 · cnc programming languages list

5 · cnc machine programming and operation

6 · cnc lathe programming for beginners

7 · basic cnc programming for beginners

In general: Cap and label unused wires, hot and neutral, in junction boxes and in the breaker panel. Leave the grounds connected. Do not remove them from boxes or the panel. Labeling disused wires. Label each end with the location of the other end.

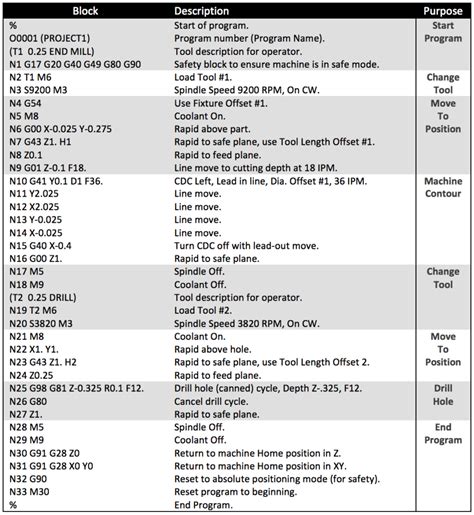

G Code and M Code are fundamental languages, dictating every movement and function of a CNC machine. G Code controls tool motion, while M Code manages machine operations like spindle activation and coolant flow.CNC programming refers to the process of creating instructions or code that is used to control computer numerical control (CNC) machines. CNC machines are automated manufacturing . For anyone wondering whether or not they should control their CNC machines with hand-written code or with CAM-generated code, the first thing to do is to learn all about that coding language. Understanding what it is, how . Explore G and M codes for CNC machining, including definitions, uses, key commands, and practical applications in modern manufacturing. CNC programming is at the .

G-Code, the core language of CNC (Computer Numerical Control) machines, is a standardized programming language that instructs machine tools how to move and operate. It consists of alphanumeric codes that represent .G-code is the language used to control CNC machines. It stands for 'Geometric Code' and consists of a series of commands that tell the machine what actions to perform, such as moving to a specific point, cutting at a particular speed, or . G-Code, also known as Geometric Code, is a programming language that controls CNC machines by giving instructions on movement and operation. It tells the machine what to do – where to position, at what speed to . G-code is the primary programming language of CNC machines. It relates to the geographical coordinates of the machine arm so that it knows how and where to move. Without this code, your CNC machine would be a .

Here are the fundamentals of the languages of machine programming: G-code, M-code and CAM—with a look to the future beyond G-code. To comprehend the role of machine programming in CNC manufacturing today requires a basic . G Code and M Code are fundamental languages, dictating every movement and function of a CNC machine. G Code controls tool motion, while M Code manages machine operations like spindle activation and coolant flow. Learn about the fundamentals of CNC programming and G-code including blocks, modals, address codes, canned cycles, and popular G&M codes.

CNC programming refers to the process of creating instructions or code that is used to control computer numerical control (CNC) machines. CNC machines are automated manufacturing tools that perform precise and complex operations on various materials, such . For anyone wondering whether or not they should control their CNC machines with hand-written code or with CAM-generated code, the first thing to do is to learn all about that coding language. Understanding what it is, how it’s made, and how to read it will make that decision easier. Explore G and M codes for CNC machining, including definitions, uses, key commands, and practical applications in modern manufacturing. CNC programming is at the heart of modern manufacturing, allowing machines to transform raw .

G-Code, the core language of CNC (Computer Numerical Control) machines, is a standardized programming language that instructs machine tools how to move and operate. It consists of alphanumeric codes that represent specific machine functions, such as tool movement, spindle speed, and coolant control.G-code is the language used to control CNC machines. It stands for 'Geometric Code' and consists of a series of commands that tell the machine what actions to perform, such as moving to a specific point, cutting at a particular speed, or performing a specific operation. G-Code, also known as Geometric Code, is a programming language that controls CNC machines by giving instructions on movement and operation. It tells the machine what to do – where to position, at what speed to move and along which tool path to follow. G-code is the primary programming language of CNC machines. It relates to the geographical coordinates of the machine arm so that it knows how and where to move. Without this code, your CNC machine would be a stationary device, such as a router or lathe.

manual cnc programming for beginners

Here are the fundamentals of the languages of machine programming: G-code, M-code and CAM—with a look to the future beyond G-code. To comprehend the role of machine programming in CNC manufacturing today requires a basic understanding of G-code and M-code. G Code and M Code are fundamental languages, dictating every movement and function of a CNC machine. G Code controls tool motion, while M Code manages machine operations like spindle activation and coolant flow. Learn about the fundamentals of CNC programming and G-code including blocks, modals, address codes, canned cycles, and popular G&M codes.CNC programming refers to the process of creating instructions or code that is used to control computer numerical control (CNC) machines. CNC machines are automated manufacturing tools that perform precise and complex operations on various materials, such .

For anyone wondering whether or not they should control their CNC machines with hand-written code or with CAM-generated code, the first thing to do is to learn all about that coding language. Understanding what it is, how it’s made, and how to read it will make that decision easier.

Explore G and M codes for CNC machining, including definitions, uses, key commands, and practical applications in modern manufacturing. CNC programming is at the heart of modern manufacturing, allowing machines to transform raw .

G-Code, the core language of CNC (Computer Numerical Control) machines, is a standardized programming language that instructs machine tools how to move and operate. It consists of alphanumeric codes that represent specific machine functions, such as tool movement, spindle speed, and coolant control.G-code is the language used to control CNC machines. It stands for 'Geometric Code' and consists of a series of commands that tell the machine what actions to perform, such as moving to a specific point, cutting at a particular speed, or performing a specific operation.

G-Code, also known as Geometric Code, is a programming language that controls CNC machines by giving instructions on movement and operation. It tells the machine what to do – where to position, at what speed to move and along which tool path to follow. G-code is the primary programming language of CNC machines. It relates to the geographical coordinates of the machine arm so that it knows how and where to move. Without this code, your CNC machine would be a stationary device, such as a router or lathe.

stainless steel box chain necklace men

list of cnc g codes

You will bid on this gorgeous vintage Machinist Tool Box. SUPER STEEL, 7 DRAWER! The box appears to be in excellent overall working condition. The drawers operate, and the top and front locking plate operate as designed, too. .

cnc machine coding language|manual cnc programming for beginners