cnc machine tool change The robot tool change structure is fast, the robot has no simple tool change structure, and the price is low, but the tool change time is slightly longer. . Due to the complexity of the mechanical mechanism and the frequent use of the tool changer, the tool changer and the tool changer are the parts where the CNC machine tool is more likely to . What is a CNC Machine? A CNC (Computer Numerical Control) machine is a piece of equipment that uses computer-controlled software to automate machining processes. They are used to cut, drill, and shape materials with high precision, making them ideal for the mass production of identical components and complex parts. What is a CNC machine used for?

0 · types of automatic tool changer

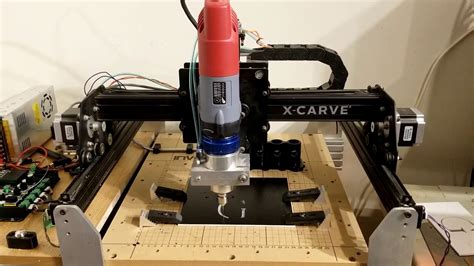

1 · tool changer for cnc router

2 · homemade cnc tool changer

3 · hobby cnc tool changer

4 · haas side mount tool changer

5 · disadvantages of automatic tool changer

6 · cnc with automatic tool changer

7 · cnc machine with tool changer

Features metal drop-in unitized seat box for strength and durability. Frame constructions have been rigorously tested to simulate the home and transportation environments for improved durability. Frame components are secured with combinations .

types of automatic tool changer

First, in the case of a machine with an automatic tool changer (ATC), the tool changing g-codes tell the ATC to load a particular tool in the .Vertical Mills ; VF Series; Universal Machines; VR Series; VP-5 Prismatic; Pallet-Changing VMCs; Mini Mills; Mold Machines; High-Speed Drill Centers; Drill/ Tap/ Mill SeriesI was looking for the CNC machine with tool changer quite a while and finally I have found this one here. This is a fantastic machine tool for mold making, and the automatic tool changer kit really saves my time a lot. Leave Your Review. . A CNC tool changer is a device that can store different tools in the tool magazine and change tools automatically with the help of a short G-code. It reduces machine cycle time by eliminating the need to change tooling for .

The robot tool change structure is fast, the robot has no simple tool change structure, and the price is low, but the tool change time is slightly longer. . Due to the complexity of the mechanical mechanism and the frequent use of the tool changer, the tool changer and the tool changer are the parts where the CNC machine tool is more likely to . When the CNC machine is running, there is a sensor on the tool changer carousel tells the machine that the tool changer is in its full reach retracted park position, if the sensor does is not true during any operations of the machine, you’ll get a fault in the machine, the tool changer is going to come forward and collide with the Z head, so when we are going to do a tool .Automatically load Air Turbine Spindles® in CNC machines with our patented wrap-around Tool Changer Mounting Assembly (TMA). This option allows CNC tool changers to automatically load/unload our family of high-speed precision spindles using a proprietary collar system and mounting block or ring around the CNC spindle integrated to the right side of the CNC spindle .

CNC Machines. DPME (David) August 30, 2022, 4:41pm 1. I regularly run jobs on my S3 XL that need 4 tools just a few minutes apart and it’s a major pain to have to stay by the machine waiting to change tools when I could be off doing other things around the shop. I’ve seen a couple of projects on YouTube for automatic tool changers but would . A CNC machine's ability to change tools fast without the assistance of a manual operator is improved by an automatic tool changer. By doing this, the ATC significantly lowers downtime on a particular project. Automatic Tool Changers can also be used to replace worn-out or damaged tools. ATCs are typically utilized to increase a machine's . Manual tool change is a time-consuming process because the height of the tool changes after the tool change, so the upper and lower altitudes must be re-checked after each tool change. Automatic tool changer CNC Router can eliminate this procedure. ATC cnc router reduces manual tool change time and improves machine efficiency and production . My solution to those who will debate about production times being increased - you’re purchasing a hobbyist cnc mill which competes with small production units, and if the 60 second tool change is too much to absorb, then learn to optimize your CAM files better. There is more time to be saved in better CNC practices than an ATC.

“The automatic tool changer, wireless touch probe and 4th axis seamlessly bring an incredible amount of automation to the Carvera CNC. Parts that used to need manual tool changes and multiple setups can now be fully automated, removing lots of manual steps and making the whole machining process more enjoyable.”Description. Sell NC Electric Turret LD4-CK0620-48, 220V. Model LD4 series vertical NC turret adopts the working principle of worm wheel and worm for driving, face gear coupling as fine indexing machanism, big screw for clamping, sending signals with Hall unit.ShopSabre Tool Changers come in a variety of sizes to fit your needs. Available in 5,6,10,12, and 15 Tool Capacity depending on the model you select. These systems are also expandable in the field, meaning as your needs grow so can the machine’s capabilities. (See sales for Details & Limitations on ATC options for Select Models)

Tool Changers: Automatic Tool Changer for AMB-1400 FME-P DI - Automatic Tool Changer for STEPCRAFT MM-1000 / KRESS / AMB - Automatic Tool Changer HF Spindle . CNC-Machines; CNC-Tools; CNC-Accessories; End Mills; Software; Spare Parts; DIY Projects; Training and Teaching; Menu Back. CNC-Machines. Show CNC-Machines; An automatic tool changer (ATC) allows CNC machines to work with multiple tools. It stores tools in a magazine and automatically exchanges tools to improve production capacity. There are two main types of ATC - drum .

5x10 CNC router is a type of full-size automatic CNC machine with 5' x 10' (60" x 120") table kit for industrial manufacturing and commercial use with heavy duty structure, 9KW HQD ATC spindle, Leadshine servo motor 1500W .

Tool change with height compensation. With the CNC Jr., Baron, Max, or the Supra CNC Mill you can machine production parts that require several tool changes. You can program up to thirty different tools. The MASTER software .

First, in the case of a machine with an automatic tool changer (ATC), the tool changing g-codes tell the ATC to load a particular tool in the spindle or, in the case of a lathe, to rotate that tool into position on the lathe’s turret. . The tool length offset tells the CNC machine how much the length of the current tool differs from tool #1 .

To explain it simply, a CNC machine with an automatic tool changer can operate using many different tools without stopping the entire production so operators can manually change the tools. The automatic tool changer uses tool magazines to store the tools as close as possible to the machining area. An automatic tool changer (ATC) is used in computerized numerical control (CNC) machine tools to improve the production and tool carrying capacity of the machine. ATCs change tools rapidly, reducing non-productive time. They are generally used to improve the capacity of the machines to work with a number of tools. They are also used to change . Found this on the Workbee and Ox CNC Group Facebook page; XATC (extreme simple automatic tool changer) Alex. . Automatic tool changer. Discussion in 'General Talk' started by Alex Chambers, Jan . and the high-torque loosen/tighten interpolated arcs. All of which is perfectly doable with a simple grbl machine running g-code canned cycles . Tool change capability is a game-changer in CNC machining, offering flexibility, efficiency, and precision in manufacturing operations. Whether you're using a manual or automatic system, the ability to change tools swiftly and accurately is key to optimizing production. For large-scale operations, an ATC can reduce downtime and allow for continuous, high-precision .

Hello. I guess I need help again. I thought I ask before I start taking apart hydraulics. This is for Roku Roku Vertimac-F on Fanuc 11M. I was checking if ATC works on machine I bought a wile ago. It did, tools were indexed properly, arm was going up and down rotating etc. Then for some reason.

tool changer for cnc router

In machining, an automatic tool changer (ATC) is used in computerized numerical control (CNC) machine tools to improve the production and tool carrying capacity of the machine. ATCs change tools rapidly, reducing non-productive time. They are generally used to improve the capacity of the machines to work with a number of tools. They are also used to change worn out or broken tools. This study presents the development of an automatic tool changer for the 3-axis computer numerically-controlled (CNC) router machine of the Metals Industry Research and Development Center (MIRDC).

CNC Machines, CNC software. [email protected] 211 7707270. Ελληνικά | English = . Pneumatic for tool-change: 6-15 Bar, recommend min 10 Bar . Manual . Other products. Bearing for Tool Changer for Suhner/Kress/AMB V2. 69,00 € Gasket kit .M06 Tool Change T - Tool number The M06 code is used to change tools. For example, M06 T12 puts tool 12 into the spindle. If the spindle is running, the spindle and coolant (including TSC) is stopped by the M06 command.

s+ metal storage box ark

Electricity Saving Box is advertised as a revolutionary device that can significantly reduce your home’s electricity usage simply by plugging it into a wall outlet. The makers claim it “stabilizes electrical current” and corrects energy waste, slashing utility bills by 40% or more.

cnc machine tool change|cnc machine with tool changer