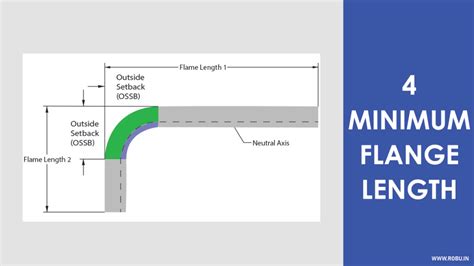

what is a flange in sheet metal The minimum recommended sheet metal flange bend length avoid cracks in the bending area. It shall be equal to three times of sheet thickness plus bend radius. Minimum Sheet Metal . Recessed Outlet/Electrical Box Single Gang, Recessed Outlet Box for Wall .

0 · sheet metal minimum flange length

1 · sheet metal guidelines pdf

2 · sheet metal enclosure design guide

3 · minimum bending radius sheet metal

4 · hole to distance sheet metal

5 · flange length in sheet metal

6 · flange calculation sheet

7 · extruded hole in sheet metal

$37.00

sheet metal minimum flange length

Sheet metal flanges offer strength, versatility, and ease of assembly. They improve the reliability and functionality of sheet metal components by providing structural support, sealing surfaces, and mounting surfaces.The minimum recommended sheet metal flange bend length avoid cracks in the bending area. It shall be equal to three times of sheet thickness plus bend radius. Minimum Sheet Metal .

1960 chevy impala metal sheet manual

In custom sheet metal fabrication, a flange is a feature consisting of a face with a bend that connects to an existing face. Flanges can add strength to precision sheet metal parts and provide a more finished edge along the .The raw and flange corner joint is a type of sheet metal joint that closely resembles a plain lap joint and involves a flat stock piece joined to a 90-degree bend to form the corner. To join the .In a bent sheet metal part, the flange length is the distance from where the punch bends the metal, to the edge of the part, or to the next major feature like another bend. In an air bending operation in particular, the amount of flange area left .

Sheet Metal Fabrication is the process of forming parts from a metal sheet by punching, cutting, stamping, and bending. 3D CAD files are converted into machine code, which controls a machine to precisely cut and form the sheets .Flanges serve as a common method of connecting pipes, valves, pumps, and other equipment. They typically have a circular shape and are fastened to equipment using bolts and nuts. Usually crafted from metal, flanges feature flat .

Minimum flange length on sheet metal parts must be at least 4 times the material thickness. It is recommended to use the same radii across all bends, and flange length must be at least 4 times the material thickness.Published September 23, 2020. An overview of minimum bend radii and bend orientation. Bending is a common sheet metal operation used to create flanges, curls, and seems. Additionally, sheets with bends are stiffer than their flat .Hi, I am inexperienced with SW sheet metal; I have inherited a bunch of drawings, and I can tell the views to use flat patterns, but when I do the edge flanges remain bent. Other sheet metal features are flattened, but not the edge flanges. Can anyone suggest why this is the case?

A sheet metal offset is different than a flange and is not a special process. If Inventor can product a flat pattern it needs to have the capability to represent bends and offsets differently. This is not "special" process, this is sheet metal 101. Yes I can model an offset with two bends, but that creates to bend lines on my flat pattern that . Flanges are important parts that are used widely in various mechanical systems. Read this guide to know what is a flange, the different kinds, and uses. . Hello! I'm Austin Peng. I manage a factory that specializes in CNC machining, injection molding, and sheet metal fabrication for small quantity production and rapid prototyping solutions .The middle portion as a Base Flange with the cutouts included in the sketch. Edge Flange for the 2 flanges bent in the same direction, then edit both sketches under that feature. Edge Flange the remaining flange and edit the sketch for it. I have created a fairly simple sheet metal part, long rectangle shaped base-flange with 2 short sketched bends, and then I add a miter flange to one side. The flange is added with no problem, except the "Miterbends" are not placed in the feature, if .

Minimum flange length on sheet metal parts must be at least 4 times the material thickness. It is recommended to use the same radii across all bends, and flange length must be at least 4 times the material thickness. Hems. We form both open and closed hems. The tolerance of a hem is dependent upon the hem’s radius, material thickness, and . I have created what I feel is very simple geometry for a small steel flange part. It is a reverse engineered bracket made in the 1930's and formed in a press tooling. I created the sketch geometry in two offset planes. I set up my sheet metal defaults and when I try the lofted flange command nothing I do will create a useful output. I need to be able to create a flat . A tapered flange is one in which the bend line dimension is deliberately produced. Forming such bends can be a challenge. Your piece with symmetrical angled edges (the center blank in Figure 2) also can form unevenly. . I have presented sheet metal training programs for the last 23 years as the Fabricators & Manufacturers Association’s .If i do all three as the same flange so the corners are nice, then I need to figure out a way to extend that back piece up further than the sides. Again, creo let me add an edge flange at 0 degrees to extend it, but SW won't let me do this. This is very frustrating because it's such a simple thing but I'm struggling with it. Thanks

Splitting in the proximity of a stretch flange is one of the most common forming failures that occur in sheet metal stamping. What is Stretch Flange? Also known as a tension flange , a stretch flange is a part feature in which the metal is bent along a concave or convex axis. This curvature forces the material to stretch from a short length of .A base flange is the first feature in a new sheet metal part. When you add a base flange feature to a SOLIDWORKS part, the part is marked as a sheet metal part. Bends are added wherever appropriate, and sheet metal specific features are added to the FeatureManager design tree.This is Solidworks video tutorial for sheet metal feature. It explains to use Miter flange in solidworks for creating extra flanges to edges in sheet metal p.

Solidworks sheet metal is a great way to create, design, and prototype sheet metal parts. It is used in a wide range of industries including automotive, aerospace, and more. There are two types of Solidworks sheet metal: the Flattened Pattern and the Sheet Metal Forming. The Flat Pattern is used when you want to create a 2D pattern of the 3D model.Die Operation to Flange Sheet Metal. Sheet metal flange operations are usually much simpler than draw operations. Often, part flanges are made in dies that are accomplishing other operations, too. Engineers bear in mind that dies and their components are costly. Rather than building one die that'll perform a flange operation and another die to .A flange wall is an attached secondary wall, dependent on a first wall. It has an open cross-sectional sketch that is extruded or swept along a trajectory. An attachment edge can be linear or nonlinear. The surface adjacent to the . When you bend metal, it does not bend evenly from the middle. The inside scrunches less then the outside stretches. The K-factor for the metal is a constant used by calculations to determine exactly how much metal is used in a bend. This is important for unfolding to know exactly how much metal you need to start with.

The flanges are typically matched to the size and pressure rating of the piping system, with bolts passing through holes in the flanges to tighten and secure the connection. The gasket material is chosen based on the specific . In a flat or closed hem, the part of the edge that bends sits completely flush over the rest of the metal sheet. The angle between the returning flange and the sheet metal is 180 degrees. The inside radius is zero and thus, there is no . Explore 7 key techniques to enhance sheet metal parts' strength and durability, from material selection to advanced bending methods. . whereas in an open hem, there remains an air pocket between the folded flange and the sheet metal. What is the hem allowance for sheet metal? A general rule for hem allowance is 43% of the material thickness . With the introduction of SOLIDWORKS 2012, that has all changed. SOLIDWORKS now has a new feature available in sheet metal that will allow you to create “Rolled Edge Flanges”. Its called “Swept Flange”. With this new feature, you now have the ability to create complex sheet metal parts and create flat patterns that go along with them.

I am facing issue of of 2 flange corner and edge overlapping or edge seam in fusion 360 sheet metal. I am currently using Creo 2.0 where we have edge treatment option to control the overlap of the edges and also have option to make corner relief as zero. Will you please tell me how to make such parts in sheet metal of fusion 360Study with Quizlet and memorize flashcards containing terms like When creating a sheet metal____, create the profile in that shape from the start., Base Flange, Bend Allowance Options and more.

A tear drop hem is a flange that has been bent more than 180 degrees. We use teardrophems for materials that lack the flexibility required of closed hems. . We shape our open hems by forming sheet metal to 145 degrees, then inserting a shim and flattening the material onto itself with the shim in place. Common gap sizes are 060”, .090 .Optional: Check Override Rules to override one or more values from the Sheet Metal Rule. Click OK. The contour flange is created and joined to the sheet metal body in the canvas, bending a the selected sheet metal edge. A Flange feature displays in the Timeline. Create a lofted flange. On the Sheet Metal tab, select Create > Flange.

If the value of sheet metal K factor and bending flange length is known. Sheet Metal flat length can be calculated in the following three steps. Step-1: Calculate the value bend allowance for the required sheet metal bend by using the below formula. Bend Allowance (BA) = (Π/180) × .The backup block also lessens the possibility of buckles, splits, or cracks. Finally, trim the flanges of excess metal, planish, remove burrs, round the corners (if any), and check the part for accuracy. Forming by Bumping As discussed earlier, bumping involves stretching the sheet metal by bumping it into a form and making it balloon.It’s a setting when you create your base flange. I think it’s also a setting if you are creating edge flanges. Relief type should have a drop down including obround. . need help manufacturing sheet metal? want to post your fabrication for all to updoot? come to r/sheetmetal to discuss all things sheet metal. Design, Fabrication .

sheet metal guidelines pdf

sheet metal enclosure design guide

1965 lincoln continental sheet metal thickness

minimum bending radius sheet metal

$54.99

what is a flange in sheet metal|sheet metal minimum flange length