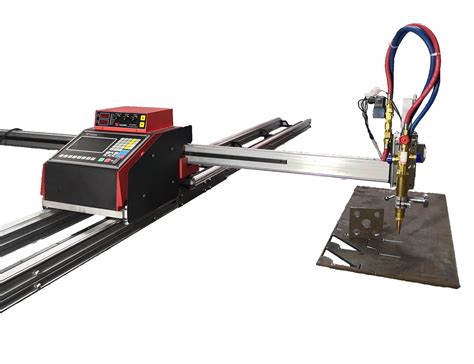

build your own cnc plasma cutting machine Ever thought about building your very own CNC plasma cutter? We all know that feeling of satisfaction when we create something with our very own hands, right? Having spent countless hours around plasma cutting tables, . Unlike gas metal arc welding (GMAW), in which you basically point and shoot, SMAW requires a higher skill level and a mastery of certain techniques. By following a few simple tips, even beginners can learn how to spot common .

0 · the best plasma cutter tables for my budget and needs

1 · cnc plasma cutting machine hobby

2 · cnc plasma cutter for hobbyist

3 · best consumer rated plasma cutter

4 · best cnc plasma cutting machine

5 · best affordable cnc plasma cutter

6 · affordable cnc plasma cutting tables

7 · affordable cnc plasma cutting machine

Discover how to choose the right fasteners for your sheet metal projects, exploring options like PEM nuts, rivets, and weld studs for optimal results.

Ever thought about building your very own CNC plasma cutter? We all know that feeling of satisfaction when we create something with our very own hands, right? Having spent countless hours around plasma cutting tables, .

🔑🔥 Unlock the power of plasma cutting with this affordable CNC table. A great DIY project for expanding the capabilities of your garage workshop.CNC Table .These are computer controlled machines that can cut through any electrically conductive material (steel / stainless / aluminum / copper). The machine takes a 2D computer generated sketch .In this blog post, we will guide you through the process of building your own DIY CNC plasma cutting machine. From sourcing the necessary components to assembling the machine and . Providing a step-by-step walkthrough for how to build your very own DIY CNC plasma table, with a list of required tools and equipment.

While industrial-grade CNC plasma cutting machines can be expensive, building your own DIY version can be a cost-effective and rewarding alternative. In this blog post, we will guide you .Solidworks has a suite of tools for working with sheet metal and allows you to build, test & analyse assemblies of parts so you can build and run your whole project before cutting any metal. This plasma table is a good example of just that!

the best plasma cutter tables for my budget and needs

As promised, here is my set of free CNC plasma cutting table plans. They are not perfectly completed but there is enough information in the layout and detail dimensions to . CNC Plasma Cutting Machine Free Plans - Sneak Peak! I've been working on an affordable CNC Plasma machine. It utilizes a seldom used center lead screw and stationary gantry style of design. I chose to do this because it . Ever thought about building your very own CNC plasma cutter? We all know that feeling of satisfaction when we create something with our very own hands, right? Having spent countless hours around plasma cutting tables, I can vouch for the thrill it brings to craft your custom machine.

🔑🔥 Unlock the power of plasma cutting with this affordable CNC table. A great DIY project for expanding the capabilities of your garage workshop.CNC Table .These are computer controlled machines that can cut through any electrically conductive material (steel / stainless / aluminum / copper). The machine takes a 2D computer generated sketch and translates it to a computer numerical control (CNC) system that is coupled with a Plasma Cutter. Building a CNC plasma table at home is as awesome as it sounds, albeit a little dangerous. Learn how to use computer controlled motion to automatically and precisely move around the plasma stream to cut metal.In this blog post, we will guide you through the process of building your own DIY CNC plasma cutting machine. From sourcing the necessary components to assembling the machine and fine-tuning its performance, we will cover it all.

Providing a step-by-step walkthrough for how to build your very own DIY CNC plasma table, with a list of required tools and equipment.

While industrial-grade CNC plasma cutting machines can be expensive, building your own DIY version can be a cost-effective and rewarding alternative. In this blog post, we will guide you through the process of creating your own CNC plasma cutting machine from scratch.Solidworks has a suite of tools for working with sheet metal and allows you to build, test & analyse assemblies of parts so you can build and run your whole project before cutting any metal. This plasma table is a good example of just that! As promised, here is my set of free CNC plasma cutting table plans. They are not perfectly completed but there is enough information in the layout and detail dimensions to finish this machine. I also included the bill of materials table that includes the purchase items which is . CNC Plasma Cutting Machine Free Plans - Sneak Peak! I've been working on an affordable CNC Plasma machine. It utilizes a seldom used center lead screw and stationary gantry style of design. I chose to do this because it allows you to you a single drive motor and less drive components than having a dual drive x-axis system.

Ever thought about building your very own CNC plasma cutter? We all know that feeling of satisfaction when we create something with our very own hands, right? Having spent countless hours around plasma cutting tables, I can vouch for the thrill it brings to craft your custom machine.🔑🔥 Unlock the power of plasma cutting with this affordable CNC table. A great DIY project for expanding the capabilities of your garage workshop.CNC Table .

These are computer controlled machines that can cut through any electrically conductive material (steel / stainless / aluminum / copper). The machine takes a 2D computer generated sketch and translates it to a computer numerical control (CNC) system that is coupled with a Plasma Cutter. Building a CNC plasma table at home is as awesome as it sounds, albeit a little dangerous. Learn how to use computer controlled motion to automatically and precisely move around the plasma stream to cut metal.In this blog post, we will guide you through the process of building your own DIY CNC plasma cutting machine. From sourcing the necessary components to assembling the machine and fine-tuning its performance, we will cover it all. Providing a step-by-step walkthrough for how to build your very own DIY CNC plasma table, with a list of required tools and equipment.

While industrial-grade CNC plasma cutting machines can be expensive, building your own DIY version can be a cost-effective and rewarding alternative. In this blog post, we will guide you through the process of creating your own CNC plasma cutting machine from scratch.

Solidworks has a suite of tools for working with sheet metal and allows you to build, test & analyse assemblies of parts so you can build and run your whole project before cutting any metal. This plasma table is a good example of just that! As promised, here is my set of free CNC plasma cutting table plans. They are not perfectly completed but there is enough information in the layout and detail dimensions to finish this machine. I also included the bill of materials table that includes the purchase items which is .

cnc plasma cutting machine hobby

The all-welded 1145 industrial storage cabinet features 14-gauge steel construction. Each of the heavy-duty steel doors include three 5/16-inch diameter brass-pin hinges. These hinges allow easy opening and closing of the doors while maintaining the door alignment.

build your own cnc plasma cutting machine|best affordable cnc plasma cutter