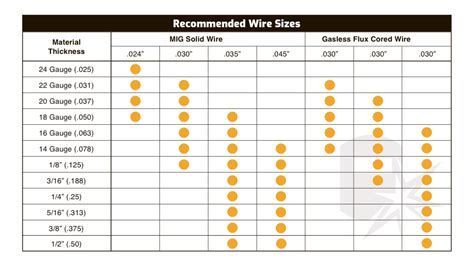

mig wire size for sheet metal A MIG wire size chart provides recommended wire diameters for different metal thicknesses. Standard sizes range from 0.023 to 0.045 inches for welding various metal gauges. Selecting the appropriate MIG wire size is crucial for successful welding. Shop for steel sheet at America's Metal Superstore. Largest selection of Hot Rolled Steel Sheet, Cold Rolled Steel Sheet, Galvanized Steel Sheet at wholesale prices. Any Quantity, Any Size, Delivered Anywhere!

0 · welding wire diameter chart

1 · welding thickness chart

2 · welding mig wire size chart

3 · weld wire selection chart

4 · mig wire diameter chart

5 · mig welding wire size selection

6 · mig welding wire size explained

7 · mig welding sheet metal basics

If the metal expands, the circle grows. A hole in the metal would grow too. This effect is actually used occasionally to fit pipes together. One is heated so it expands, slipped over the other, .

A MIG wire size chart provides recommended wire diameters for different metal thicknesses. Standard sizes range from 0.023 to 0.045 inches for welding various metal gauges. Selecting the appropriate MIG wire size is crucial for successful welding. The welding wire size chart is a crucial guide for selecting the right welding wire size, which varies according to material thickness and type of welding. It ensures optimal weld quality, appropriate amperage, and effective .

The most common sizes for welding on sheet metal are 0.35 and 0.45. MIG Wire selection chart – See full-size version here. Wire Quantity. In making a MIG wire purchase, .

The choice between 0.8 mm and 0.9 mm MIG wire depends on the thickness of the metal being welded. 0.8 mm wire is suitable for welding thin metal sheets up to 3 mm thick, while 0.9 mm wire is better suited for thicker metals . This article will teach you the essentials of MIG and flux-cored wires, their types, and why you should use one over the other. We will also discuss each type in short with a focus on ..34

.34 Using 0.023, 0.024, and 0.030 in MIG solid wires for sheet metal is best. Also, avoid a 100% CO2 shielding gas because it amplifies penetration, which leads to burn-through. The best shielding gas for MIG welding thin mild .

As a guideline, each .001 inch of material thickness requires 1 amp of output: .125 inch = 125 amps. Select proper wire size according to amperage. Since you don't want to change wire, select one for your most commonly used . MIG Welding: What Size Wire Should I Use? TimWelds. 389K subscribers. 3.6K. 193K views 3 years ago. A hands on look at the two MIG welding wire sizes that I would . It’s recommended to use a .023- or .024-inch wire for most light gauge sheet metal work. When the material is 18-gauge and thicker, you may be able to use a .030-inch wire. To weld mild steel, choose an American Welding . Welding sheet metal with Mig wire requires you to consider the following essential factors. Use a Correct Mig Wire Size for Different Gauge Sheet Metal; If you are welding light gauge sheet metal, a .023- or .024-inch wire is .

welding wire diameter chart

There seems to be much difference of opinions on which size wire works best on sheet metal (22 g- 18 g) I've always used .030 in my MM210, harris 20 gauge in my 110 machine. I was wondering what others opinions/results were with .023 or .030. . Great 240V small Mig Hobart Handler 140 - Great 120V Mig Hobart Handler EZ125 - IMO the best 120V .

welding thickness chart

Once clamped, the panels are tack welded together, spacing the tacks no more than 1 inch apart. Every welder has their own preferences for sheet metal. I’m using 0.023-inch ER 70 S-6 filler wire and 15 cfh (cubic feet per . Ensure that you use very thin wires when welding with delicate, thin sheet metal. Metal Thickness (inches) Recommended MIG Wire Size (inches) 0.024: 0.020: 0.030: 0.023: 0.036: 0.025: 0.048: 0.030: 0.060: 0.035: 4. Consider Pulsing. In addition to your regular MIG welding technique, you can experiment with pulsing when working with thin metals . You can do a couple of things to combat this extra heat, the first of which is picking the right wire size. In general, don’t use a wire that is thicker than your sheet metal. If you’re welding 1mm thick steel sheet metal, then you’ll want to use an 0.6mm wire for the best results, although 0.8mm would also work.This chart is a helpful guide for choosing the correct wire size and type (solid or flux) of wire based on the thickness of the material being welded. All Categories. Welding . WIRE SIZE CHART. RECOMMENDED WIRE SIZES. MIG SOLID WIRE: GASLESS FLUX-CORED WIRE: MATERIAL THICKNESS.024".030".035".045".030".035".045" 24 Gauge (.025) X: 22 Gauge .

A hands on look at the two MIG welding wire sizes that I would recommend for most people.****Affordable self-paced welding courses taught by me****https://co.

I welded up some sheet metal with my new to me MM250 with the standard .035 wire. The tack, tack, tack method worked great for me and can be fast once you get into it. This was my second actual MIG weld I done going from the sheet metal to 1/4" box tube. Weld Wire If you are patching sheet metal I would use .018 wire, I have been welding for a very long time, pipe fitting and everything. On a smaller machine like a 120 volt/220volt MIG that would be the best, low heat and not a .

0.6 mm sheet metal (car-stuff e.g.) you can only use 0.6 mm. wire, because when using 0.8 wire the heat needed for melting the wire would have melted/blown holes in the sheet. At first glance, this sounds logical, but is it true? And in this situation, a welder-setting of ~23 Amps would be needed (according to the rule:

As is always the case in MIG welding, it is critically important to match the wire type to the base metal. So if you are welding an aluminum base metal, you will need to go with an aluminum wire. . Choose a MIG Wire Size Suitable for Car Panels. The three most common wire sizes in MIG welding are 0.035″, 0.030″, and 0.023″. Of these . What is .045 MIG wire used for? 0.045 inch (1.2 mm) MIG wire is typically used for welding thicker materials, such as structural steel and heavy fabrication. What size MIG wire is best for sheet metal? For sheet metal, use a smaller wire size like 0.023-0.030 inch (0.6-0.8 mm) for better control and less heat input. Using 0.023, 0.024, and 0.030 in MIG solid wires for sheet metal is best. Also, avoid a 100% CO2 . Stick welding is not a delicate process but with a proper setup and rod size, you can weld sheet metal with the SMAW . Also, reduce the tungsten, stick electrode, or MIG wire diameter to the lower amperage accordingly. Appearance.

Yep. C25 is 25% carbon dioxide, 75% argon which is the correct mixture for welding steel. Lighter wire for the sheet metal and heavier for the thicker metal (duh). If you're new at welding, use scrap to test it on. Wire speed and amps are key on the mig - too much wire and too little amps will give you a lot of splatter and not much bond. The filler metal deposition rate is slower than FCAW, but it’s less likely to burn through the thin sheet metal. There are many different sizes and MIG welding wire types. So, let’s quickly go through the MIG wire specs and .

1 emt junction box

In this video I share with you some awesome mig wire I found for sheet metal. This welding wire is great for rust repair and any sheet metal work. This wire .

1 inch electrical box extender

To weld sheet metal you need a tig or mig with the gas bottle. These to welder you can weld at lower temps. . Minimize wire size from 20 to 24; Most migs have an adjustable (reversible) wire size drive wheel and must be set to the smaller wire size.) 3. Use the chain tack weld process until fully welded out.The most crucial parameters include voltage, amperage, and wire speed. The challenge of choosing the correct parameters is that they depend on the thickness of weld metal, wire size, type of metal, joint configuration, welding position, or shielding gas. So there is no universal approach to MIG welding thin metal, but there is a solution.

Using the correct MIG welding settings can make or break the quality of your finished product. Use these tips to get the best MIG welds. . If a manual or weld specification sheet is not available, use the multipliers in the following chart to find a good starting point for wire feed speed. For example, for .030-inch wire, multiply by 2 inches . The .025 mig wire will be fine for sheet metal. One question I have is what polarity are you using? Mig and flux core welding require different polarity connections. mig must have positive electrode polarity, flux core must have negative electrode polarity.

Adapting your welding technique to accommodate different positions is essential for maintaining consistency and weld integrity across various sheet metal applications. MIG Welding Sheet Metal Settings. Achieving optimal MIG welding settings for sheet metal hinges on precise control over voltage and wire feed speed. Mild/carbon steel – ER70s wire and 75/25 percent ratio of Argon to CO2; Stainless – ER308L wire and 98 percent Argon with 2 percent CO2; Aluminum – ER4043 wire and 100% Argon shielding; You choose your wire size by the amperage setting, which in turn depends on material thickness. Here are the most-used wire sizes in MIG welding. Instead, you need to choose the wire size according to the thickness of the metal you’re welding. For example, when welding sheet metal, the most common wire sizes are 0.35 and 0.45 inches. However, when welding thin steel, you’ll probably need a solid MIG wire with a smaller diameter, either 0.24 or 0.30 inches. In doing some research about MIG welding sheet metal, I've noticed some folks recommend using .023 wire for vehicle applications of 16g - 20g sheet. I'm trying to understand the differences between .023 and .025 as it relates to the wire itself, tips, and drive roll. - .

When starting to learn auto body sheet metal welding with a MIG welder, you should opt for a shielding gas that has a higher proportion of argon gas. It is better to use instead of a high percentage of CO2. . It is better to avoid using a flux-cored wire when welding sheet metals. It will make the base metal more susceptible to heat. How to . For thinner gauge sheet metal like 18 or 20 gauge we suggest .023 (6mm) wire in your MIG welder. Keep the Stick Out Short-Stickout of your MIG wire is important when welding any type of metal, but especially sheet metal. Holding the tip too far from the surface will cause the wire to have to come out too far to touch the metal. This means the .

The voltage and wire feed speed vary though. A 0.024-inch wire would operate at 13 to 15 volts (electrode positive) with a wire feed speed of 130 to 160 ipm, whereas the 0.30-inch solid wire would require 15 to 17 volts and 75 to 100 ipm wire feed speed. These parameters would work well for single-pass flat and horizontal fillet welds.

welding mig wire size chart

Protect essential wiring connections in any home or workplace with durable junction boxes from Toolstation. Find electrical and lighting junction boxes in various amperages to suit different applications. We stock standard electrical boxes in 5A to 30A with 3 to 6 terminals.

mig wire size for sheet metal|welding mig wire size chart