sheet metal working process pdf Sheet metal fabrication is the process of forming parts from a metal sheet by punching, cutting, stamping, and bending. 3D CAD files are converted into machine code, which controls a . Your fabric will be cut in one continuous piece. Help others learn more about this product by uploading a video! Looking for specific info?

0 · sheet metal stamping process pdf

1 · sheet metal operations with diagrams

2 · sheet metal operations pdf

3 · sheet metal manufacturing process pdf

4 · sheet metal forming process pdf

5 · sheet metal die design pdf

6 · sheet metal design calculations pdf

7 · forming operation in sheet metal

LaLaGreen Window Boxes Planters for Outdoor Plants (2 Pack, 16 Inch) White Metal Rectangular Wall Hanging Planters Deck Railing Flower Box with Coco Liners, Trendy Horse Troughs Balcony Patio Porch

SHEET METALWORKING. Cutting and forming thin sheets of metal usually performed as cold working. Sheet metal = 0.4 (1/64) to 6 mm (1/4in) thick. Plate stock > 6 mm thick. Advantage. .Sheet Metalworking. Cutting and forming operations performed on relatively thin sheets of metal which are produced by rolling. Thickness of sheet metal = 0.4 mm (1/64 in) to 6 mm (1/4 in) .Introduction. Cutting and forming thin sheets of metal usually performed as cold working. Sheet metal = 0.4 (1/64) to 6 mm (1/4in) thick. Plate stock > 6 mm thick. Advantage - High strength, .

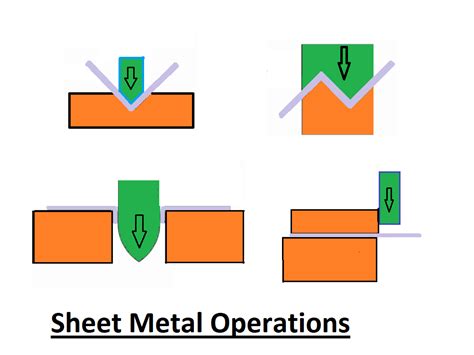

shearing, bending, stretching are the most common processes for working with sheetmetal to create parts that meet our design intent. SHEARING. cutting sheet metal by subjecting it to .Sheet metal fabrication is the process of forming parts from a metal sheet by punching, cutting, stamping, and bending. 3D CAD files are converted into machine code, which controls a .Metal Forming Process. Forming can be defined as the process in which the desired size and shape of the object are obtained through plastic deformation of material. The stresses induced .

The objective of this work is to provide an overview of the factors that influence the quality of the sheared edge, speed limitations, and life of tooling elements in the sheet metal shearing .describe various tools, machines and operations which are widely used in sheet metal shop, sketch the various types of Tin-Smithy joint, describe the process of soldering and brazing, .

Chap 2 , sheet metal – p. 1 Sheet Metal Forming Processes • involves workpieces with a high ratio of surface area to thickness • plates, thickness > ¼ inch • sheets, thickness ≤ ¼ inch • typical items produced by sheet-metal forming processes: metal desks appliance bodies . hubcaps aircraft panels . beverage cans car bodiesProcess design is the ensemble of operations leading from the design geometry to the dieface. . all other factors influencing sheet metal forming, we should recall that a sheet metal forming operation can always be, from the conceptual point of view, divided in two stages:Classification of metal working processes : Download: 22: Mechanics of metalworking and analysis methods : Download: 23: Determination of flow stresses in metal working : Download: 24: Hot working and cold working : Download: 25: Metallurgical considerations in metal forming : Download: 26: Introduction and classification of forging processes .

sheet metal stamping process pdf

Sheet Metal Working - Free download as PDF File (.pdf), Text File (.txt) or view presentation slides online. The document discusses sheet metal forming operations. Sheet metal thickness typically ranges from 0.4 mm to 6 mm, with thicker materials called plate and thinner called foil. Common forming operations include cutting, bending, and drawing. And drawing is cup or deep drawing when the cup depth is more than half its diameter [3]. A typical deep drawing process to produce a cup is shown in Fig 1. Fig 1: Deep Drawing Process [19] 2.1. Process parameters Every sheet metal process is governed by various parameters. In case of drawing the following parameters play a significant role.SHEET METALWORKING - Michigan State University Download Citation | Sheet Metal Shearing Process: An Overview | Even after the development of various non-conventional processes for sheet metal cutting, the shearing process remains the most .

ºõ³ . An appropriate process model structure for the purpose of controller design for the sheet metal forming process is presented and the parameter estimation for this model is accomplished using .

Barbecue Grill Manufacturing Process analysis (Report) - Free download as PDF File (.pdf), Text File (.txt) or read online for free. this report is a research of design a Barbecue Grill and designs the facility that could manufacture it with deciding of .

Download file PDF Read file. Download file PDF. Read file. . Sheet Metal F orming - Bending, . A wire drawing is a cold working process in .sheet metal working - Free download as PDF File (.pdf), Text File (.txt) or read online for free. Sheet metalworking involves cutting and forming thin sheets of metal between 0.4 mm and 6 mm thick. Common sheet metals include low-carbon steel which is inexpensive and easy to form. Sheet metal is used widely in transportation and manufacturing for parts that require strength, . PDF | Metal Forming Processes, Bulk forming,Sheet metal forming | Find, read and cite all the research you need on ResearchGate . Extrusion is a bulk forming process in which the work metal is .

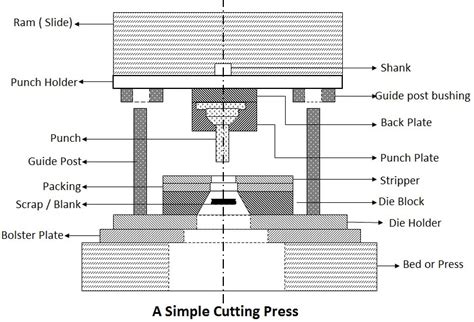

Sheet Metal Working & Process 2/17/2016 Compiled & Edited by SIVARAMAN VELMURUGAN 12 Sheet Metal Forming Process Large group of manufacturing processes in which plastic deformation is used to change the shape of metal workpieces. The tool, usually called a die, applies stresses that exceed the yield strength of the metal The metal takes a .Sheet Metal Working - Presses: PDF unavailable: 11: Sheet Metal Working - Equipment: PDF unavailable: 12: High Energy Rate Forming Processes: PDF unavailable: 13: . Welding Process Classification: PDF unavailable: 29: Brazing Soldering Braze Welding: PDF unavailable: 30: Arc Welding Power Source Part - 1:

Page 2 : 100, , , , sheet Metal Working 117, ¢ Production rates are rapid. Formin, , 8 Speeds can run as hi, average of 50 to 100 f¥/imin for m igh as 300 ft/min for some shapes and, , Ost applications., e The low labour cost and the savings in material cost, quantities are large enough to Pay off the initial tooling a, Disadvantages of Sheet Metal Forming are—, , provide .the forming process, and the fact that dimensional variation is introduced at each bend, dimensioning in a single direction parallels the process and helps to control tolerance accumulation. Furthermore, allow a more generous bend tolerance (+/- .007”) as tighter tolerances, while achievable, will result in higher costs.

sheet metal operations with diagrams

Forging is the oldest metal working process. Because it just requires heating and hammering of metals, man found it easy. The following forging operations are performed. Drawing down or swaging: The process of increasing length and decreasing cross sectional area of the metal is known as drawing. The compressive force (hammering or pressing) areSheet Metal Stamping Stamping presses and stamping dies are tools used to produce high volume sheet metal parts. The press provides the force to close the stamping dies where they shape and cut the sheet metal into finished parts. Production stamping is generally performed using sheet metal materials .020” to .080” thick, but the processSheet Metal Working.pdf - Free download as PDF File (.pdf), Text File (.txt) or view presentation slides online. Sheet metal working involves cutting and forming thin metal sheets between 0.4mm and 6mm thick. The main sheet metal processes are cutting, bending, drawing, and forming using dies and presses. Common sheet metal products include automotive, aircraft, and appliance .2.3 General sheet processes (plane stress) 16 2.4 Yielding in plane stress 17 2.5 The flow rule 22 2.6 Work of plastic deformation 24 2.7 Work hardening hypothesis 25 2.8 Effective stress and strain functions 26 2.9 Summary 27 2.10 Exercises 27 3 Deformation of sheet in plane stress 30 3.1 Uniform sheet deformation processes 30 3.2 Strain .

Sheet Metalworking • Forming and related operations performed on metal sheets and strips • High surface area-to-volume ratio of starting metal, which distinguishes these from bulk deformation • Often called press working because presses perform these operations Parts are called stampings Usual tooling: punch and dieRolling is the most important metal working process and can be performed on either hot or cold metal. The work is subjected to high compressive stresses from the squeezing . stress forming, where a metals sheet is wrapped to the contour of a die under the application of tensile forces. Bending involved the bending moment to the sheet while .Sheet Metal Working - Free download as Powerpoint Presentation (.ppt / .pptx), PDF File (.pdf), Text File (.txt) or view presentation slides online. Sheet metal working involves forming and cutting operations performed on metal sheets, strips, and coils using presses and tools like punches and dies. Common sheet metal operations include bending, drawing, shearing, blanking, piercing, .

Sheet metal workers' manual; a complete, practical instruction book on the sheet metal industry, machinery and tools, and related subjects, including the oxy-acetylen welding and cutting process by Broemel, L. (Louis), b. 1885; Daugherty, James S. (James Sharkey), b. 1866WORKSHOP REPORT sheet metalworking - Free download as Word Doc (.doc / .docx), PDF File (.pdf), Text File (.txt) or read online for free. The document is a workshop report for a course on technology and handwork practice. It discusses sheet metalworking and provides details about the tools, processes, and activities involved. The objectives are to expose students to sheet .

junction box cover plastic

junction box electrical circuit

Vinyl jamb liners from Fenster are the easiest way to repair the balance of your double-hung windows. Kits come fully assembled with all hardware and are available in two colors. Jamb Liner Kits include: a heavy-duty block and tackle balance; matching tilt pins; 15-degree sill angle; flange mounting for a quick & easy installation. COLOR OPTIONS

sheet metal working process pdf|sheet metal stamping process pdf