sheet metal forming processes slides Manufacturing Engineering Technology in SI Units, 6th Edition Chapter 16: Sheet-Metal Forming Processes and Equipment Presentation slide for courses, Sheet Metal Forming Deep drawing. . AMALCO offers superior contract metal fabrication capabilities, including deep drawing and hydroforming metal forming processes. Our manufacturing equipment includes components designed exclusively by and for Amalco.

0 · sheet metal working process pdf

1 · sheet metal stamping process pdf

2 · sheet metal processes pdf

3 · sheet metal forming process pdf

4 · sheet metal forming press dies

5 · sheet metal forming by hand

6 · sheet metal bending process pdf

7 · bulk deformation vs sheet metal forming

To achieve the desired results, machining parts and components require careful planning and attention to detail. This includes selecting the appropriate machining technique and machine tool for the job, as well as determining the optimal cutting parameters such as speed, feed rate, and depth of cut.

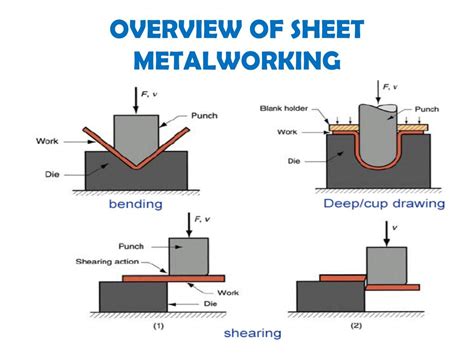

Sheet Metal Forming Sheet metal forming is a process that materials undergo permanent deformation by cold forming to produce a variety of complex three dimensional shapes. The process is carried out in the plane of . This document provides an overview of sheet metal forming processes. It discusses both cutting (shearing) operations like punching, blanking, and notching as well as forming operations like bending, drawing, squeezing, .

This document provides information on various sheet metal forming processes. It discusses the characteristics of sheet metal and tests used to determine formability. The main sheet metal forming processes covered are .Manufacturing Engineering Technology in SI Units, 6th Edition Chapter 16: Sheet-Metal Forming Processes and Equipment Presentation slide for courses, Sheet Metal Forming Deep drawing. .

Manufacturing Engineering Technology in SI Units, 6th Edition Chapter 16: Sheet-Metal Forming Processes and Equipment Presentation slide for courses, Sheet Metal Forming Deep drawing. . Sheet metal forming process is carried out in the plane of the sheet by tensile forces with a high ratio of surface area to thickness. The high rate of production and formability is determined by its mechanical properties. Sheet metal working involves cutting, bending, drawing, and other forming operations to shape metal sheets. The processes include shearing, blanking, and punching, with various tools like punches and dies. Clearance, . Sheet Metal Forming Process and Their Application. Sheet metal forming process is carried out in the plane of the sheet by tensile forces with a high ratio of surface area to thickness. The high rate of production and .

Manufacturing Engineering Technology in SI Units, 6th Edition Chapter 16: Sheet-Metal Forming Processes and Equipment Presentation slide for courses,

3. Syllabus Sheet metal characteristics – shearing, bending and drawing operations – Stretch forming operations – Formability of sheet metal – Test methods –special forming processes-Working principle and applications .

Fourslide metal stamping is a metal forming process in which flat stock sheet metal, formed from metals such as steel, aluminum, zinc, nickel and titanium, etc., is shaped into predetermined parts in a stamping press. During press . 1. Metal forming processes Metal forming: Large set of manufacturing processes in which the material is deformed plastically to take the shape of the die geometry. The tools used for such deformation are called die, . Basic Types of Sheet Metal Processes 1. Cutting – Shearing to separate large sheets – Blanking to cut part perimeters out of sheet metal – Punching to make holes in sheet metal 2. Bending – Straining sheet around a straight axis 3. Drawing – Forming of sheet into convex or concave shapes 4. 1.0 Introduction Sheet metal is simply metal formed into thin and flat pieces. Sheet metal is essentially metal pressed into sheets. These sheets are used at various places. These sheets can be bent, cut and molded into any shape for use anywhere. Sheet metal is generally produced in sheets by reducing the thickness of work piece by compressive forces .

2. BULK DEFORMATION PROCESSES: Metal forming operations which cause significant shape change by deformation in metal parts whose initial form is bulk rather than sheet. These processes work by stressing metal sufficiently to cause plastic flow into desired shape. Performed as cold, warm, and hot working operations. In hot working, significant shape .Manufacturing Engineering Technology in SI Units, 6th Edition Chapter 16: Sheet-Metal Forming Processes and Equipment Presentation slide for courses, Sheet Metal Forming Deep drawing. NC State University Department of Materials Science and Engineering1 MSE 440/540: Processing of Metallic Materials Instructors: Yuntian Zhu Office: 308. 1. SHEET METAL PROCESSES Sheet metal characteristics - Typical shearing operations, bending and drawing operations – Stretch forming operations –– Formability of sheet metal – Test methods – Working principle and application of special forming processes - Hydro forming – Rubber pad forming – Metal spinning – Introduction to Explosive forming, Magnetic .Sheet Metal Forming Processes. Sheet Metal Forming Processes. Introduction. Ratio – Surface Area:Volume is very high for sheet metal process. Plates – thickness > 0.25 inches Boilers, bridges, ships, etc. use relatively thick plates Usually sheet forming is done on relatively thin material. Shapes can be of various size. 649 views • 11 .

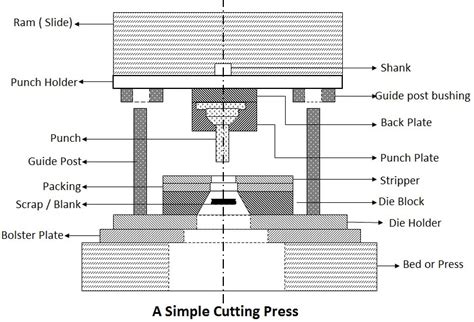

Sheet Metal Forming (MIT 2.008x Lecture Slides) - Download as a PDF or view online for free . Sheet Metal Forming (MIT 2.008x Lecture Slides) - Download as a PDF or view online for free . Stretch Forming Process 11. Manufacturing 3D Sheet Stamping for Car Bodies 2.008 Fall 201610/12/16 Simultaneous Deformation over the Area of the Part What . Sheet metal forming processes - Download as a PDF or view online for free. . Type of forming operation, and dies and tooling required Size and shape of work pieces Length of stroke of the slide, stroke per minute, speed and shut height (distance from the top of the bed to the bottom of the slide, with the stroke down) Number of slides (single . Contact us to learn more about sheet metal forming and the four slide products we offer. At Valco, we are proud to offer a complete Tool Room capable of four-slide stamping and more. 440-237-0160

Sheet Metal Forming Processes. Sheet Metal Forming Processes. Chapt 16. Shearing. Process that involves cutting sheet metal by subjecting it to shear stresses, usually between a punch and a die. Blank: removed from a large sheet or coil - part made from blank. Shearing terms. 1.24k views • 25 slides Group 9 Presentation Sheet-Metal Forming Processes Scott Currie Jared Adams Taylor Grisham Yien- Sheng Ao Joe Butner. Extrusion and Drawing of Metals. Definitions Extrusion is defined as the process of shaping material, such as aluminum, by forcing it to flow through a shaped opening in a die. Extruded material emerges as an elongated piece with the .19 Characteristics of Sheet-Metal Forming Processes Drawing - shallow or deep parts with relatively simply shapes. Explosive – Large sheets with relatively simple shapes. . Sheet-Metal Forming Processes and Equipment Presentation slide for courses, Metal Forming. (MT 207) B.Sc (ENGINEERING) LEVEL 2 (Semester 2)

Sheet Metal Forming Processes. Introduction. Ratio – Surface Area:Volume is very high for sheet metal process. Plates – thickness > 0.25 inches Boilers, bridges, ships, etc. use relatively thick plates Usually sheet .Manufacturing Engineering Technology in SI Units, 6th Edition Chapter 16: Sheet-Metal Forming Processes and Equipment Presentation slide for courses, Sheet Metal Forming Deep drawing. Characteristics of Metals Important in Sheet Forming

sheet metal working process pdf

sheet metal stamping process pdf

Sheet Metal Forming Processes Chapt 16. Shearing • Process that involves cutting sheet metal by subjecting it to shear stresses, usually between a punch and a die.. Blank: removed from a large sheet or coil - part made from blank. Shearing terms • Punching (piercing): sheared slug is discarded. • Blanking: slug is the part, the rest is discarded.

Title: SheetMetal Forming Processes 1 Sheet-Metal Forming Processes 2 Sheet-Metal Forming Processes 3 Aluminum Two-Piece Beverage Cans. FIGURE 7.77 Aluminum two-piece beverage cans. Note the fine surface finish. Source Courtesy of J. E. Wang, Texas AM Univerity. 4 Metal-Forming Process for Food and Beverage ContainersDeep drawing is a sheet metal forming process used to fabricate cup-shaped parts; . Sticking friction is when the work surface adheres to the surface of the tool rather than slides against it; it occurs when the friction stress is greater than the shear flow stress of the metal.

sheet metal processes pdf

Slide deck consisting of panel bending machine at work process of metal sheet forming Presentation design enhanced with lobnya - jun 7 automated line for forming shaped metal sheets in manufacturing workshop at plant of group of companies metal profile june 7 2012 lobnya russia

sheet metal forming process pdf

Sheet Metal Forming Processes. Sheet Metal Forming Processes. Chapt 16. Shearing. Process that involves cutting sheet metal by subjecting it to shear stresses, usually between a punch and a die. Blank: removed from a large sheet or coil - part made from blank. Shearing terms. 1.24k views • 25 slidesEver wondered what goes into shaping the metal components we use daily? The answer lies in the meticulous sheet metal fabrication process. Understanding this process is crucial for businesses and professionals in the metal industry. The sheet metal fabrication process is an intricate journey from raw metal to a finished product. It involves .Sheet Metal Forming Processes – A free PowerPoint PPT presentation (displayed as an HTML5 slide show) on PowerShow.com - id: 165fae-ZDc1Z. Toggle navigation. Help; Preferences; . Chart and Diagram Slides for PowerPoint - Beautifully designed chart and diagram s for PowerPoint with visually stunning graphics and animation effects. Our new . Deep drawing is a metal forming process in which sheet metal is stretched into the desired shape. A tool pushes downward on the sheet metal, forcing it into a die cavity in the shape of the desired part. . Simple dies or single action dies perform single operation for each stroke of the press slide. The operation may be one of the cutting or .

Deep drawing is a sheet metal forming process used to fabricate cup shaped parts bar drawing is a bulk deformation process used to reduce the diameter of a cylindrical workpart. . Sticking friction is when the work surface adheres to the surface of the tool rather than slides against it; it occurs when the friction stress is greater than the .

sheet metal forming press dies

INTRODUCTION Products made by sheet-metal forming processes are all around us; they include metal desks, file cabinets, appliances, car bodies, aircraft fuselages(机身), and beverage(饮料) cans. Sheet forming dates back to 5000 B.C., when household utensils(器具) and jewelry were made by hammering and stamping gold, silver, and copper.

A network of suppliers are on Alibaba.com to fulfill your steel box factory needs at wholesale price. Whatever custom design you need, we have the sheet metal fabrication options to make it a reality.

sheet metal forming processes slides|sheet metal forming by hand