sheet metal part tolerances Tolerances of Machined and Sheet Metal Parts Xometry's Manufacturing Partner Network makes thousands of machines available to make your part at the click of a mouse. Since the minimum requirement to machine a part is a solid CAD file, we offer these general tolerances and guidelines (also found in our Manufacturing Standards ). $26.99

0 · steel thickness tolerance chart

1 · standard sheet metal tolerances chart

2 · sheet thickness tolerance chart

3 · sheet metal tolerances pdf

4 · sheet metal tolerances chart

5 · sheet metal thickness tolerance chart

6 · sheet metal gauge tolerance chart

7 · sheet metal dimensioning standards

Celebrating 76 successful years in business, United Metal Fabricators was established in 1945 to provide excellence in the tube and pipe bending industry. Since that time, we have evolved and are proud to supply companies both nationally and globally.

steel thickness tolerance chart

craftsman 26.5 in. 6 drawer steel rolling tool cabinet

standard sheet metal tolerances chart

Unlike precision machining, sheet metal fabrication begins with sheet stock, which can have variations in thickness, and the manufacturing . The first dimension, 11.20±0.25, has a tolerance equivalent to approximately ±.010 inches. This dimension alone is challenging – our standard tolerance sheet indicates that a .Tolerances of Machined and Sheet Metal Parts Xometry's Manufacturing Partner Network makes thousands of machines available to make your part at the click of a mouse. Since the minimum requirement to machine a part is a solid CAD file, we offer these general tolerances and guidelines (also found in our Manufacturing Standards ).

Sheet metal parts would cost 2-4x more if perfect accuracy was the standard. As such, only expect the raw laser cut part to be accurate. Reply reply Sharkboy242 • I get what you're saying completely, and its good insight. . Normally sheet .Sheet Metal Guage Tolerances During the rolling process the rollers bow slightly, which results in the sheets being thinner on the edges. The tolerances in the table and attachments reflect current manufacturing practices and commercial standards and are not representative of the Manufacturer's Standard Gauge, which has no inherent tolerances.Tolerances: Sheet metal tolerances should not be tighter than necessary to make the part functional. Tight tolerances raise the cost of manufacturing significantly. Practical tolerances vary according to the design requirements. Tolerances of +/- .010 should be considered minimum. Linear tolerances should be held as loose as possible.

Actual tolerances in sheet metal fabrication are influenced by various factors, underscoring the necessity of engaging with your fabricator at the initial stages of design. . Sheet metal parts and designs generally incorporate a number of standard design features that improve part utility, strength, rigidity or other properties based on the .1) All manufacturing tolerances used up to that point (such as laser-cutting tolerances, welding tolerances and more) 2) All bend tolerances for the entire part, added together We call this an uncontrolled dimensions because there are additional tolerances to consider.

covers for steel outlet boxes

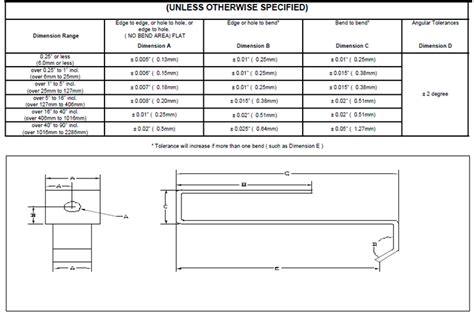

Recommended Default Sheet Metal Tolerances Default Tolerances (Millimeters) DIM Tolerance Description A ± 0.13 Sheared Edge to Hole . H* ± 0.76 Formed Part Default Tolerances (Inch) DIM Tolerance Description A ± 0.005 Sheared Edge to Hole B ± 0.005 2 Holes on One Surface C ± 0.010 Formed Edge to Hole D* ± 0.030 Holes Across 2 Bends E .Part 1 General Tolerances ISO 2768-1 ISO 2768-1 is intended to simplify drawing indications and specifies general tolerances in 4 tolerance classes (f – fine, m – medium, c – coarse, v – very coarse). . Vacuum Casting, Injection Molding, Sheet Metal Fabrication. Permissible deviations in mm for ranges in nominal lengths Tolerance .Comprehensive resource of fabrication tolerances and dimensional variation guidelines for sheet metal manufacturing and fabrication. Transform your team's workflow with . • Protocase commits to supply parts to the dimensional tolerances noted in this resource, unless we have agreed to other tolerances when quoting your job. Overview . Table of Contents. 1 How Powder Coating Adds Thickness to a Metal Fabricated Part. 1.1 Adjusting tolerances to account for powder coating buildup ; 2 Proactive Designs Pave the Way for Optimal Powder Coating Results; 3 Recommended Default Sheet Metal Tolerances; 4 Sheet Metal Powder Coating Tolerance FAQ. 4.0.1 How does powder coating affect the .

Sheet metal tolerances help manufacturers align components and ensure optimal performance. Tolerancing is crucial for most industries. . They can also reduce production costs, shorten lead times, and improve part performance. Risk Mitigation. Sheet metal tolerancing allows engineers to mitigate manufacturing risks for different industries and .IS 2102-1 (1993): General tolerances, Part 1: Tolerances for linear and angular dimensions without individual tolerance indications [PGD 20: Engineering Standards] IS 2102 ( Part 1 ,) : 1993 IS0 2768-l : 1989 . removal or parts that are formed from sheet metal. NOTES 2 These tolerances may be suitable for use with materials other than metal. To the uninitiated, sheet metal and plate bending looks simple enough, but the truth is that it’s often the most complicated process on many metal fabrication shop floors. Theoretically, it shouldn’t be complicated. . By a “handy guide,” Benson means a guideline specifying reasonable tolerances for a formed part, .

based on the design of the desired part. Flat Parts Flat sheet metal parts that utilize stock material gauge thicknesses and require no bending or milled features. All flat sheet metal parts can meet a +/-0.005” (+/- 0.127mm) tolerance. Multiple Surface Bends For dimensions measured over mul-tiple bends, Xometry can offer a +/-

Just because it's a sheet metal part, doesn't mean you can't dimension it with a tolerance tighter than +/- .015" If the part requires a tighter tolerance, it requires a tighter tolerance. The _design_ either does, or does not, require a certain level of tolerance.

These tolerance constraints apply not only when attaching two sheet metal parts together, but also when attaching sheet metal to other components such as weldments, or plastic/structural foam skins. Therefore .

dimensioning in a single direction parallels the process and helps to control tolerance accumulation. Furthermore, allow a more generous bend tolerance (+/- .007”) as tighter tolerances, while achievable, will result in higher costs. Use consistent bend radius for all bends per part, when possible—it helps minimize setup changes.

Fabrication Tolerances for Dimensional Variance in Sheet Metal and Machined Parts. Standard Tolerances For Copper. Usually, choosing material thickness is one of the first steps a designer takes when starting a project. . It's also important when working with sheet metal that you factor in finish tolerances. For example, if you add a finish . Sheet Metal Part GDT Thread starter nmine; Start date Jun 5, 2024; Status Not open for further replies. Jun 5, 2024 #1 nmine . angular tolerance in ISO 2768-1 for sheet metal process 1. kokerkov; Jan 11, 2024; Drafting Standards, GD&T & Tolerance Analysis; Replies 5 Views 85. Jan 11, 2024. kokerkov. Locked; Question;For example, the manufacturer recommends ISO 2768-mk for sheet metal parts and ISO 2768-fh for machined components. In the above example, “m” and “k” have defined the tolerance class. You can calculate the critical dimension tolerance using tolerance stack-up analysis. You can also use a tolerance stack-up calculator for this purpose. Industry Standards for Sheet Metal Tolerances. Different international guidelines standards are set for sheet metal tolerances. These guidelines and standards guarantee quality and consistency across different manufacturers and industries. ISO 2768. ISO 2768 is an important standard for general tolerances in sheet metal fabrication.

BY PRESS WORKING FROM SHEET METAL AND SHEAR FROM METAL PLATES TECHNICAL DATA TECHNICAL DATA Table 1. General dimensional tolerance of blanking Unit:mm 1. General dimensional tolerances for parts formed by press working from sheet metal Basic size step Grades G rad eA B C Over 1000 to 2000 incl. Over 400 to 1000 incl. Over 120 .

Common Standards for Dimensional tolerances. We adhere to various standards in sheet metal fabrication. ISO 2768 is the most widely used standard for general tolerances, while ANSI Y14.5 is more specific. These standards serve as a guide to ensure consistency in production regardless of the project’s complexity.. It’s not just about compliance; it’s about . Form Tolerance: By specifying form constraints, GD&T ensures that the flatness, straightness, roundness, and profile of sheet metal parts are within acceptable limits. Orientation Tolerance: GD&T controls the angularity, perpendicularity, and parallelism of features, which is vital for parts that must align correctly with other components. tolerances describe the range of variations permissible in a dimension, let's delve into the types of tolerances involved in sheet metal fabrication. +1(213) 398 9420 +86 13922902420

Fabrication Tolerances for Dimensional Variance in Sheet Metal and Machined Parts Finish Tolerances When it comes to surface finishes, it's important to factor them into your overall design, as our surface finishes can add anywhere from 0.0004" to 0.003", depending on the finish. The resulting bend angle variation, and sometimes the required adjustment to the flat layout, contributes to the reason that machined parts (typical tolerance of ±0.002 in.) can routinely have tighter tolerances than precision sheet metal parts (typical tolerance of ±0.010 in.).

In the classic operation of nesting and bar machining centers, the table remains static holding the workpiece while the machine head (consisting of electrospindle and boring unit) performs the machining.

sheet metal part tolerances|sheet metal tolerances pdf