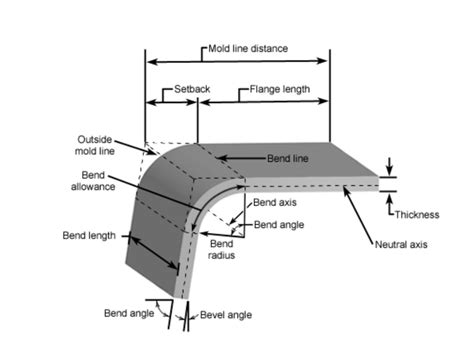

radius rule for sheet metal K-factor, bend allowance/deduction, and outside setbacks all affect sheet metal design. Learn about them to avoid issues during your design process. W & D Sheet Metal Inc is located at 2648 37th Ave S in Minneapolis, Minnesota 55406. W & D Sheet Metal Inc can be contacted via phone at 612-729-0589 for pricing, hours and directions. Contact Info

0 · steel plate bend radius chart

1 · sheet metal radius bending tool

2 · sheet metal inside bend radius

3 · sheet metal bending chart

4 · minimum bending radius sheet metal

5 · large radius sheet metal bending

6 · bending steel plate minimum radius

7 · bend radius chart sheet metal

Remove existing box, replace with Single gang box or 1900 with mud ring supported by threaded rod to structural framing depending on chandelier weight. Patch, spackle, sand and paint around where new box doesn’t cover.

Bend Radius- As a rule, inside bend radius should be equal to material thickness. When the radius is less than recommended, this can cause material flow problems in soft material and . A typical recommendation is 1t for all sheet metal parts, which means the smallest bend radius should be at least equal to the sheet thickness. For example, if the thickness of the sheet is 2mm, the minimum bend radius .

custom part manufacturers

K-factor, bend allowance/deduction, and outside setbacks all affect sheet metal design. Learn about them to avoid issues during your design process. The following are some design rules for slots and holes. Hole and slot in sheet metal design. 1. The minimum hole diameter should be ( Dmin) ≥ the thickness of the sheet . To ensure the bending strength of the sheet metal, the bending radius should be greater than the minimum bending radius specified for that particular sheet metal material. The minimum bending radii for various .

Sheet Metal Bending Calculation. Bend Allowance (BA) BA = [(0.017453 × Inside radius) + (0.0078 × Material thickness)] × Bend angle, which is always complementary. The length of the neutral axis is calculated as a .

custom metal parts holder

To achieve the correct sheet metal bend radius, it is crucial to use proper techniques, equipment, and tooling. Using the appropriate press brake and metal bending tools and following proper air bending or metal bending procedures . A general rule of thumb for bending sheet metal is that the minimum bend radius should be equal to the material thickness of mild steel, 1.5 times the material thickness of stainless steel, and similar to or less than the . Choose the right bend radius for the material and thickness of the sheet metal. Use proper bending techniques, such as air bending or bottom bending, depending on the desired bend angle. Consider the tooling .DFMPro for Sheet Metal Design Guidelines. DFMPro provides pre-configured design guidelines DFM rules for design which helps to develop better quality parts at reduced cost. Some of the common sheet metal design guidelines included .

custom metal parts manufacturer

Sheet metal bending is a versatile field that allows for designs ranging from complex to simple to be created in a cost effective and efficient manner.As with all manufacturing processes and design applications, specific .

Sheet metal bending: designing guidelines . Rules for Designing Bends. The basic bending design guidelines that a designer needs to consider when modelling a sheet metal component include wall thickness, bend radii, and .Sheet metal design guidelines are followed for sheet metal enclosure and part design to ensure the first time right product and reduce cost. . Recommended inside bend radius for sheet metal parts should be equal to material thickness. For hard materials (Stainless steel, CRCA), an inside bend radius equal to 0.65 times of sheet thickness is . How does Fusion 360 handle sheet metal bending rules, like radius. Is it up to me to state or are there suggestions.. or what? I am building a 19" 3U (5.25" high) rack mount enclosure. I am about done with the front panel. So now it is on to the cage or actual enclosure with bends and PEM nuts. This will be made with 1/16" aluminum sheet. It might be .To edit the sheet metal rule, click the Edit Sheet Metal Rule button on the dialog. In the Sheet tab of the Style and Standard Editor dialog, you can set the sheet preferences such as . slot radius. 15. Click Dimension on the Constrain panel and select the round end of the slot. 16. Click to display the Edit Dimension box.

Here’s a good rule of thumb for most materials: The inside bend radius should be equal to the thickness of the material that you’re forming. . You also get a nice round fold, since the 2×4’s will have a radius which will transfer to the sheet metal – your bends will actually be nice and strong.

Forum rules Be nice to others! Read the FreeCAD code of conduct! 2 posts • Page 1 of 1. FIBMCad . so I use sheet metal workbench. I have a problem: every time that I make a bend, I have to change internal bend radius (Ri) and k-factor (Kf), because FreeCAD set them to default values (Ri=1 and Kf=0,5). .

The Rule of Thumb for Sheet Metal Bend Radius. Sometimes, you need a quick reference without digging into charts. That’s where the rule of thumb comes in. It’s a practical approach to estimating bend radius based on the thickness of the material. We’ll delve deeper into this handy rule to make your life easier. How does Fusion 360 handle sheet metal bending rules, like radius. Is it up to me to state or are there suggestions.. or what? I am building a 19" 3U (5.25" high) rack mount enclosure. I am about done with the front panel. So now it is on to the cage or actual enclosure with bends and PEM nuts. This will be made with 1/16" aluminum sheet. It might be .

steel plate bend radius chart

sheet metal radius bending tool

The part was start using a multibody part, 1. extrude and get two 3mm thick solids , 2. then use bend to join those two individual solids to make one bent solid 3. make the ipt part using a sheet metal template If a couple of sheet metal rule have been set up for different bend radius & different thickness in the sheet metal template When bend at step 2, how can i get . First, here’s a quick review. As a rule of thumb, what does the 20 percent rule state? It states that the radius of sheet metal and plate forms as a percentage of the die opening. The rule’s name comes from stainless steel, which generally forms a radius that’s 20 to 22 percent of the die opening.

The sheet metal design rule of thumb in this case is: The distance between the sheet metal bend line and edge of the hole should be two times or greater the thickness of the sheet metal. Minimum Sheet Metal Bending Radius: Minimum sheet metal bend radius depends on the selection of tool and the process. The more ductile the sheet metal, the .

sheet metal inside bend radius

Just a few are the forming method (air forming, bottoming, or coining), the type of bend (sharp, radius, or profound radius bends), the tooling you are using, and the multibreakage of the workpiece during large-radius bending. Also, the farther past 90 degrees you go, the smaller the inside radius will physically become.Bend Radius. Sheet metal bend brakes are used to bend material into the parts desired geometry. Bends that are in the same plane need to be designed in the same direction to avoid part re orientation, to save both money and time. .Create and Name a New Sheet Metal Rule. To create a sheet metal rule, copy the supplied Default rule (or an existing rule) and make and save changes to the selections and values on all three tabs.. Click Manage tab Styles and Standards panel Styles Editor to open the Style and Standard Editor dialog box.; Click the expand/collapse “+” to the left of the Sheet Metal Rule .

So it seems I need to do the following: 1) Set up a rule that tells inventor that when using this specific sheet metal style to use the material thickness for all bend angles that are not 90degress 2) For all other bends to .

Press brakes have a variable radius being 3 points and 1 variable: V die= 2 points, punch= 1 point, depth= variable. For example when you only bend a piece of sheet metal a slight bend it will have a larger radius then that exact same piece of sheet metal on the the exact same punch and V die set bent more will have a smaller radius. What is the Right Bend Radius for Sheet Metal? Below is Xometry’s minimum bend radius reference table which is based on theoretical sheet metal gauge thicknesses. Thickness of the sheet: Minimum bend radius: 1–6 mm: 1 time the thickness of .

Sheet metal bending can be done using many methods. We discuss those along with springback, bend allowances, k factor, design tips etc. . Rule of Thumb for Minimum Bend Radius. Keep it simple. What could be simpler than choosing the inner radius (ir) just the same as the material thickness? This avoids later troubles, overthinking and silly .The bend radius is a critical parameter in sheet metal fabrication, dictating the minimum radius one can bend a metal sheet without significant deformations. Calculating the correct bend radius is essential for ensuring the structural integrity and aesthetic of the finished product. . the 20 percent rule, suggests that the initial inside . How does Fusion 360 handle sheet metal bending rules, like radius. Is it up to me to state or are there suggestions.. or what? I am building a 19" 3U (5.25" high) rack mount enclosure. I am about done with the front panel. So now it is on to the cage or actual enclosure with bends and PEM nuts. This will be made with 1/16" aluminum sheet. It might be .

Bend Allowance Chart. The bend allowance chart is an essential resource for professionals working with sheet metal fabrication. It provides a comprehensive listing of key parameters such as material thickness, bending radius, bending angle, bend allowance, and bend deduction values for common materials.

I'm interested in bending a piece of sheet metal to a specific radius. In one case the sheet will be formed from 6092 aluminum. In another case the sheet will be formed from 304 stainless steel. I need to be able to bend these sheets without cracking the outer surface of the bend. However, I need to form these sheets to a radius ~ sheet thickness. Table of Contents. 1 Common Bend Radius Design Mistakes; 2 Sheet Metal Part Design for Manufacturing Tip. 2.0.1 UNABLE TO UNFOLD PART, SHEET METAL BEND RADIUS ISSUE RESOLVED; 3 How to implement the industry standard sheet metal bend radius. 3.1; 3.2 Your Partner in Precision Sheet Metal Design; 4 Sheet Metal Part Design for Manufacturing .The general rule for transverse pitch in unlimited overlap is? 4. What is the minimum bend radius of a sheet metal? Don't know? Terms in this set (51) The limits for pitch in three rows or more are? 3D min and 12D max. The general rule for transverse pitch in unlimited overlap is?

Depth: The depth of your relief should be at least the material thickness + the bend radius + .02” (0.5mm) measured from the outside of your bend. That extra .02” provides just a little added clearance. . The first is in the initial Sheet-Metal feature that is created when your part is made using the sheet metal tools (or converted to .

custom part manufacturer of stabiliser

custom metalized boxes

Find the right solution for powering your equipment outdoors. Shop Our Inventory Of Weatherproof Boxes And Accessories Online. Graybar Is Your Trusted Distributor For Electrical Boxes.

radius rule for sheet metal|steel plate bend radius chart