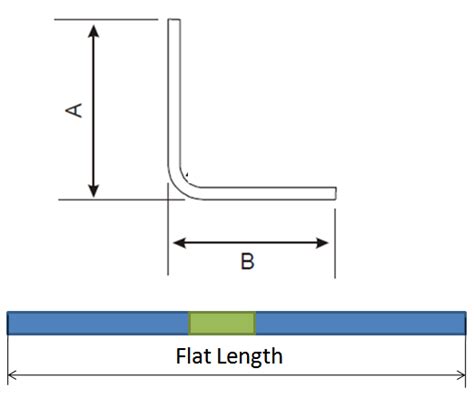

developed length of sheet metal After bending a sheet metal part, the total length of sheet metal is more than the flat length. This change in length can be represented as bend deduction or bend allowance. This . Anyone ever hear of "live tooling" or "dynamic live tooling" in verticle mills? What is Live tooling versus "non-live tooling"? Of all the tool holding types I have used, I like VDI style holders for lathes the best, and HSK style holders for mills/routers the best.

0 · sheet metal flat length formula

1 · sheet metal flat length

2 · sheet metal development length formula

3 · sheet metal design length formula

4 · sheet metal bend length

5 · metal sheet development formula

6 · metal sheet development calculation

7 · how to calculate a metal sheet

Designed to control the flow of conditioned air into an occupied space, single duct terminal units can be used in almost any application. A variety of accessories are available to tailor this unit to specific applications including those with stringent requirements for noise levels, temperature, and energy efficiency.

After bending a sheet metal part, the total length of sheet metal is more than the flat length. This change in length can be represented as bend deduction or bend allowance. This .Bend allowance calculations are used to determine the developed length of flat sheet metal required to make a bend with a specific radius and angle. These calculations are important to . The calculation formula for the expanded length of beveled press-brake sheet metal is: [L = A + B + C + 0.2], where (A), (B), and (C) represent the internal dimensions, and 0.2 serves as a compensation value.How to calculate accurate developed sheet metal length? Sheet metal bending is an important sheet metal manufacturing process. Accuracy of the finished sheet metal bending product depends entirely upon accurate calculation of bending .

With this bend allowance calculator, you will learn how to calculate the length of a sheet metal bend so you can optimally create metal bendings without a bend allowance chart. It works as a bend deduction calculator too!Illustrated here is the development of a blank for parts having a standard 90 deg. bend. Shown is a common dimensioning method and calculation of a Setback (bend deduction) * SB = .Accurate calculation of developed lengths is crucial for precise sheet metal fabrication. DIN 6935 provides specific formulas and correction factors that account for bending angles, bending .

You can calculate the developed length of sheet metal parts using bend calculation tables. With bend calculation tables, you can define different angular ranges, assign equations to those ranges, and calculate the developed length . A physics-based model for calculating bend allowance and developed length for a strain hardening sheet metal formed by pressbrake bending is presented. Effects of material properties and. We go better with a practical example; with a thickness of 1,5 m/m and to calculate the development of the following sheet (see sketch) we will do the next calculation: 70 – (2 x 1,5) + 25 – (2 x 1,5) + 15 = 104 m/m is the length of the piece (before being bended).

sheet metal flat length formula

After bending a sheet metal part, the total length of sheet metal is more than the flat length. This change in length can be represented as bend deduction or bend allowance. This bend allowance and bend deduction are calculated using a constant known as the K factor or Y factor.Bend allowance calculations are used to determine the developed length of flat sheet metal required to make a bend with a specific radius and angle. These calculations are important to create an accurate flattened model for manufacture. The calculation formula for the expanded length of beveled press-brake sheet metal is: [L = A + B + C + 0.2], where (A), (B), and (C) represent the internal dimensions, and 0.2 serves as a compensation value.

How to calculate accurate developed sheet metal length? Sheet metal bending is an important sheet metal manufacturing process. Accuracy of the finished sheet metal bending product depends entirely upon accurate calculation of bending allowance. With this bend allowance calculator, you will learn how to calculate the length of a sheet metal bend so you can optimally create metal bendings without a bend allowance chart. It works as a bend deduction calculator too!

best cnc machine to make money

Illustrated here is the development of a blank for parts having a standard 90 deg. bend. Shown is a common dimensioning method and calculation of a Setback (bend deduction) * SB = Setback: The amount to be subtracted from the sum of the outside dimensions of the two legs of the bent part; the object is to determine the correct length of the flat.Accurate calculation of developed lengths is crucial for precise sheet metal fabrication. DIN 6935 provides specific formulas and correction factors that account for bending angles, bending radius, and material characteristics.You can calculate the developed length of sheet metal parts using bend calculation tables. With bend calculation tables, you can define different angular ranges, assign equations to those ranges, and calculate the developed length of the part. A physics-based model for calculating bend allowance and developed length for a strain hardening sheet metal formed by pressbrake bending is presented. Effects of material properties and.

We go better with a practical example; with a thickness of 1,5 m/m and to calculate the development of the following sheet (see sketch) we will do the next calculation: 70 – (2 x 1,5) + 25 – (2 x 1,5) + 15 = 104 m/m is the length of the piece (before being bended).After bending a sheet metal part, the total length of sheet metal is more than the flat length. This change in length can be represented as bend deduction or bend allowance. This bend allowance and bend deduction are calculated using a constant known as the K factor or Y factor.Bend allowance calculations are used to determine the developed length of flat sheet metal required to make a bend with a specific radius and angle. These calculations are important to create an accurate flattened model for manufacture.

The calculation formula for the expanded length of beveled press-brake sheet metal is: [L = A + B + C + 0.2], where (A), (B), and (C) represent the internal dimensions, and 0.2 serves as a compensation value.

How to calculate accurate developed sheet metal length? Sheet metal bending is an important sheet metal manufacturing process. Accuracy of the finished sheet metal bending product depends entirely upon accurate calculation of bending allowance. With this bend allowance calculator, you will learn how to calculate the length of a sheet metal bend so you can optimally create metal bendings without a bend allowance chart. It works as a bend deduction calculator too!Illustrated here is the development of a blank for parts having a standard 90 deg. bend. Shown is a common dimensioning method and calculation of a Setback (bend deduction) * SB = Setback: The amount to be subtracted from the sum of the outside dimensions of the two legs of the bent part; the object is to determine the correct length of the flat.Accurate calculation of developed lengths is crucial for precise sheet metal fabrication. DIN 6935 provides specific formulas and correction factors that account for bending angles, bending radius, and material characteristics.

You can calculate the developed length of sheet metal parts using bend calculation tables. With bend calculation tables, you can define different angular ranges, assign equations to those ranges, and calculate the developed length of the part.

sheet metal flat length

best chinese small cnc milling machine

best cnc components manufacturer

BROADWAY SHEET METAL, 7855 Burnet Ave, Van Nuys, CA 91405, Mon - 8:00 am - 4:00 pm, Tue - 8:00 am - 4:00 pm, Wed - 8:00 am - 4:00 pm, Thu - 8:00 .

developed length of sheet metal|metal sheet development calculation