how get holes in a electrical box Knockouts are partially stamped, quarter-size openings in the electrical boxes. Here's how to remove a knockout in order to run wires . JACK’S METAL WORKS is Boise’s premier metal fabrication company. We specialize in creating custom projects, retail metal sales, item repair and all your other metal needs. With our large stock of ready to purchase metal & industry standard equipment, we can handle any job, big or .

0 · knock out electrical box removal

1 · holes around electrical box repair

2 · hole knockout for electrical box

3 · electrical box repair tips

4 · electrical box repair

5 · electrical box knockout removal instructions

6 · electrical box knockout drill

The following are the main welding processes used for Sheet Metal welding: Stick Welding or SMAW; Gas Tungsten Arc Welding (GTAW or TIG)

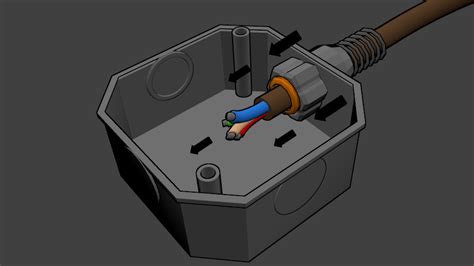

A "knock out" or "KO" is a partially stamped opening in electrical enclosures that allows quick entry of a wire, cable or pipe via connector or fitting to the interior. With the right information and technique, you should be able to remove a "KO" from electrical panels and .

In this video, I’ll go over how to drill out electrical box knockouts with a standard hole saw bit rather than buying the expensive knockout drill kit.1” Mil. In this video I'm making a holes. Holes in an electrical boxes. I have 5 different types of electrical boxes . Each is for different application.

Learn how to repair holes around electrical box video! With these contractor tips and DIY tricks! I’m going to show you how to easily fix oversized electric. Knockouts are partially stamped, quarter-size openings in the electrical boxes. Here's how to remove a knockout in order to run wires .

How to Fix a Screwy Electrical Box. I recently had to deal with a loose receptacle inside a plastic electrical box. It turned out the screw holes in the box were stripped. To fix the problem, I slipped small zip ties into the stripped .The answer is Yes you can add holes to the back of the box with a hole saw. Hole saws and slug busters are used by Electricians regularly for this. A 7/8" hole saw will provide the correct size .There are a few options for repairing a broken screw hole in a plastic electrical box. My standard choice was to replace the electrical box. The G-Clip gives me the option to repair it if possible. Sometimes the electrical box is broken more .Metal Box Mender Repairs for Stripped Screw Holes in Metal Electrical Boxes. In the U.K. inventor David Sexton provides his invention, "Metal Box Mender" a kit that "mends .

In this video I will show you how to get a knock out of a 4x4 square box.

That box is a type of plastic called Bakelite. It's tough, but brittle. If you're careful, you can break the box apart without damaging the ceiling. If you have a hole saw, you can probably drill out around the rivet heads you see in . I wired up a little switch operated outlet for my router table, which seems to work (yay). I tried to get the right box and cover, but there were a LOT to choose from. This cover has holes in all four corners, but the box only had . Several reasons actually. Here are just a few: 1. If there is not enough circuit capacity in the main box for additional circuits, 2. if circuit breakers listed for use in the main panel are no longer available, 3. it costs less .

The best way would have been to cut back to the studs on either side of the box and four inches at the top and bottom of the box, before you did any electrical work. Then you would have had all the space you needed around the box to restructure the electrical and when you were finished you would plug the hole with a new piece of 12" X 16" drywall.

I usually use a drawing program to make drawing of my box/panel that includes center marks for each hole. Then I print this 1:1, cut it out, tape it to my box/panel, and use it as a template for the center punch. Then I use a small drill bit to make a pilot hole before using a . Commonly cause of short circuit in the service equipment is the poorly output/ work done by a chiseled hole enclosures. As the sealant worn out in time due t.Take a piece of wood and make a hole in it with the hole saw for 1 1/4 pipe. Clamp it over the hole you need to make larger the wood will support the hole saw so it doesn't slide around. Another option is to try and use an 1 1/8 hole saw as the arbor for the hole saw for 1 1/4. Edit: sorry if that doesn't make sense. Whether you’re replacing an old electrical box, installing a new outlet, or making changes to the wiring, knowing how to punch out an electrical box is a valuable skill to have. Punching out an electrical box involves removing the knockout, the small metal disk or tab that covers the hole where electrical wires enter or exit the box.

I am looking to see if the NEC has any guidance on where you can cut a hole into your outdoor electrical panel. (To add a cable clamp). . It is permissible to add extra knockout holes to a cabinet or junction box; in fact, many commercial panelboard cabinets and some pull boxes ship without any knockouts, expecting the user to make their own. . After slicing 90 deg the box would be rotated 90 deg to continue the cut . . . Alternatively, the box could be held down on a flat surface and the knife held with the cutting edge away from the thumb. The removal would be with a slicing action from above then the box flipped over for slicing the remainder. Drill small hole in the center of the desired knockout (from the inside). Drive a long self-tapping metal screw into the newly drilled hole until it is firmly in place. Take a claw-hammer or kitty-paw to pull on the screw until you can get pliers .

hinges for steel storage cabinet 2.5 wide

This is Turtle. Go to any Electric supply houses and ask for a 1.5" metal snap in plug for electrical boxes. It looks like a big old type coke bottle top that snapped on to the old returniable coke bottles but it will be 1.5" in diameter. The box up there is similar to the one below. If you have attic access, you can remove the old box and replace it fairly easy. If you don't have access, then you'll have to cut the tabs the nails are in so you can remove the box. Be very careful not to cut the wires going into the box. A keyhole saw or hack saw blade with a handle works great. 110.12 Mechanical Execution of Work. Electrical equipment shall be installed in a neat and workmanlike manner. (A) Unused Openings. Unused cable or raceway openings in boxes, raceways, auxiliary gutters, cabinets, cutout boxes, meter socket enclosures, equipment cases, or housings shall be effectively closed to afford protection substantially equivalent to . Tour Start here for a quick overview of the site Help Center Detailed answers to any questions you might have Meta Discuss the workings and policies of this site

Hi Everyone. In this video I'm making a holes. Holes in an electrical boxes. I have 5 different types of electrical boxes . Each is for different application. The best way to cut out an electrical socket in porcelain and stone tiles ensuring that you get the perfect finish every time. For more information on this s. Electrical - AC & DC - Code question regarding drilling a small hole in an electric junction box - I'd like to mount the side of a metal junction box I currently have to a stud. The only mounting holes currently in the junction box are in the bottom of the box- .

In the process I have found several that have the hole where the screw goes into the electrical box broken not allowing me the screw the outlet into the box. Without having to replace the electrical box itself, is there a quick fix to be able to screw the outlet into the box? . Some brands of tan colored boxes have a metal insert at the screw . You can learn more or ask questions @ http://www.electricalindustrynetwork.com Here you can see the tools mentioned in part 1 in action. Again methods vary . I've used metal weatherproof boxes in a similar situation where the boxes needed to be mounted on the 1.5" edge of a 2 by XX. I've used a washer just big enough to cover the backside hub then shoot a screw thru the washer. That secures the box to the 2 by edge and any conduit attached to the top or bottom hubs will prevent the box from rotating.

In this video I will show you how to get a knock out of a 4x4 square box. There shouldn't be any struggling with this and after seeing a 25 year master elec.Looks like there’s only 2 wires coming in, which makes for replacing the box quite a bit easier, if you have attic access it would make it a breeze, if not carefully smash out the old box trying not to damage drywall too much, cut the mounting tabs off your new box, slide the wires in and wiggle it into place, put a couple screws through the side of it into the joist, and you’re done.Try not to get into the drywall to much because it will clog the diamond abrasive up. Finish the drywall with a plunge plade on an oscillating tool, a thin kerf keyhole saw, a utility knife, or if you don't care about a clean hole hit the flabbergaster with a . Shove steel wood into small holes and pack it in hard [not in electrical boxes w any live wires]. Forget silicone unless it's the bitter flavored one, but this is only a temp solution. All of those wires need to be rerouted into a single conduit that goes into your house. . Each end needs metal caps that fits the wire sizes and no more. Mice .

How to Fix a Screwy Electrical Box. I recently had to deal with a loose receptacle inside a plastic electrical box. It turned out the screw holes in the box were stripped. To fix the problem, I slipped small zip ties into the stripped holes, which allowed me to tighten the screws until snug. — Stan Stegelman Electrical - AC & DC - Can you drill holes in electrical panel where there are no knockouts? - I am still working on my panel upgrade. Yes, I know still! . The box is labeled "Knock Metal Set", and the other markings on the box leave a person wondering if they're getting a knockout punch set or a couple tickets to a pro wrestling match. But .

knock out electrical box removal

Welding bonds two metal pieces into one unit using heat or pressure. It is a specific step in a larger metalworking process. Key welding methods, like MIG, TIG, and stick welding, suit different project needs. While focused on metals, welders sometimes join plastics and glass, too.

how get holes in a electrical box|electrical box knockout removal instructions