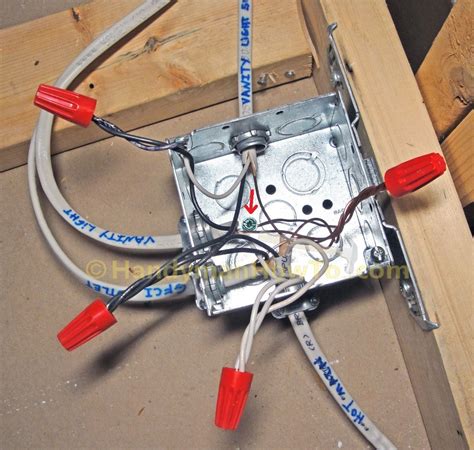

fitting wires into electrical box Welcome to our Introduction to Electrical Wiring Series: In these process videos, we review the wiring process from installing a junction box to how to wire.

What Does a Sheet Metal Mechanic Do? A sheet metal mechanic works with various thin sheets of metal materials to fabricate, install, and repair products and parts made from sheets of metal. Their direct supervisor may be a sheet metal supervisor, shop manager, production manager, or general contractor depending on their place of employment.

0 · where are junction boxes located

1 · pushing wires into outlet box

2 · junction box installation instructions

3 · installing junction box in wall

4 · install electrical junction box

5 · electrical junction box installation instructions

6 · electrical box installation instructions

7 · connecting wires in junction box

Roof and building specifications often use “gauge” when stating the required material thickness. A structural engineer will call for 20 gauge steel deck, for example, or a roof consultant will specify 24 gauge steel panels to be used in a standing seam metal roof.

Home depot has terminal blocks that you push wires into individually one at a time. Split-bolts and solid terminal blocks are common for large gagues. Here's just a few options from just one vendor. Fit the Wires in the Box . Carefully fold the wires into the box. Install the box cover, securing it with two screws. Code requires that the cover must be a solid "blank" without holes. . Use this box fill calculator to find the correct size of electrical utility box to fit the conducting wires, grounding wires, and devices or equipment you would need to install and have it pass the National Electrical Code®.Assuming no conduit - you have romex in a building, need to get it through a hole and into a box - use a watertight threaded fitting that extends into the hole in the wall and run the romex through that. Yeah, big hole. Just don't try drilling .

With the wires stripped, you are now ready to move on to the next step: connecting the wires inside the junction box. When wiring a shallow electrical box, make sure to use the appropriate size and type of wire .

Welcome to our Introduction to Electrical Wiring Series: In these process videos, we review the wiring process from installing a junction box to how to wire.Although the pictures here are by far the most extreme box fill code violations, some common sense along with electrical code requirements limits the number of wires that can be put into an electrical box. There are a number of reasons for this such as. a) Allowance for proper heat dissipation. b) Ability to trace wire cables.

Replacing ceiling fan - wires won’t fit in ceiling box . There is a step where you have to push the connected wires (in wire nuts) thru the hole of the mounting bracket, up into the ceiling box. . there is actually never a reason to use electrical tape with a wire nut; specifically because it violates the wire nut’s UL listing. .Any wiremold surface mount box. They mount to single gang boxes in the wall and provide more depth. Make sure the metal boxes are properly bonded together as the ground for the device will be dependent on the box with that old wiring. Would be best to put a grounding pigtail from the box in the wall to the wiremold box and device. There should be at least 6 inches of free wire extending into the box for connection purposes; 8 to 10 inches is even better. This excess wire provides the slack necessary to make various wire connections to devices and also provides enough excess wire in case the wires need to be trimmed off in the future.116 votes, 168 comments. I feel crazy, but my wires absolutely will not fit into these new outlets. I didn't even know this was a thing. Is there a.

where are junction boxes located

With the wires identified, you’re now ready to move on to the next step: counting the wires in the electrical box. When counting wires in an electrical box, remember to include all hot, neutral, and ground wires. Be sure to account for any wire nuts or connectors that may be hiding additional wires.One of the mistakes often made is over loading an wire electrical box with too many wires. This will cause switches and outlets to not fit correctly and could even cause wires to become damaged. This information will help you plan your electrical box size properly. . A wire running through the box counts as one wire. Each wire coming into a .Use the deepest, largest box you can fit in the wall, with the most cubic inches. Metal boxes have more cubic inches than plastic boxes. "Masonry" boxes are huge, and well worth the trouble. Trim every wire that comes into that box to about 7" length. That allows you to fold the wire into the box with one 180-degree bend.

More Details: The wires have to run for 10 feet along the joist. so I am planning to run and staple wires parallel to cable wires ( green & black) and run the wires through a 2 inches of hole (1-2 feet away from panel box) and finally pull the wires through behind joists to run into the panel box. I'll be using wire tie to group them together.Bunch of yahoos spouting as if they know something. If there's a ground in the box, you need to hook it up to the GFCI as you did. I understand you're having a problem getting it into the box. If it's an old metal box, it's going to be really tight, but it can be done, depending on configuration and the number of wires in it. A simple guide to setting up an electrical junction box Junction boxes protect electrical wires from damage, prevent shocks, and stop sparks from igniting flammable material nearby. . The color of the wire nut determines its size and how many wires can fit inside of it. For example, a red wire nut holds a minimum of two 14-gauge wires up to a .Once non-metallic sheathed cables are pulled into a box and stripped, it's time to organize the hot, neutral, and ground wires. . Learn techniques for making up fittings and securely strapping EMT to concrete and wood surfaces before running wires through it. . How to Work Efficiently in an .

Use this box fill calculator to find the correct size of electrical utility box to fit the conducting wires, grounding wires, and devices or equipment you would need to install and have it pass . plan, we need to feed 6 pieces of 12 .

I think your best bet is to get a bigger box to fit everything in. I wouldn't advise shortening wires unless they are super long. Rule of thumb is 6 inches of extra wire from front of box (9" from back) I think the extension boxes are really .

Lets say you have a 125 Amp circuit and because of the length you end up with 2/0 copper wire. The 125 amp circuit breaker lugs are not big enough to accommodate wire that large. I've encountered jobs where someone has just trimmed off enough strands to make it fit but I don't think that would pass inspection. This would require removal of the old box and this is higher in skill/tool level than just changing a receptacle. You may be able to get a GFCI receptacle which occupies less space, or you may be able to rearrange the wires in the box. Is the wiring copper? If so, is it #14 or #12? How many wires are in these boxes?

aluminum radiator mounting brackets 80 camaro

But first, let’s find out what this term means. What Are Electrical Fittings? Electrical fittings are components used to connect, secure, and protect electrical wiring in various installations. They include a variety of items designed to work together to create safe and efficient electrical connections. When UL approves the box, they also approve the labeling on the box, and the instruction sheet intended to go with the box. Of course, big-box stores buy by the carton, sell them loose in bins, and don't give you the instruction sheet. But it should be on the Internet.Have a 3 gang box. 2 smart switches and a dumb switch. Decided to add a Shelly to make the last switch smart. At the end of the day, the box has a.

aluminum junction box quotes

However, placing too many wires into an electrical box is against the National Electrical Code. . Box fill is the term used to describe the total volume of the conductors, devices, and fittings within the electrical box. Counting the number of wires seems like a simple task, but there are many factors that can affect the box fill, including .When they’re a little more flexible, it’s easier to get the wire in there. Another way is to use a flat-blade screwdriver. You don’t want to go too far because the tab still has be able to keep the wire secure. Now I’ll start feeding wires into the box. By code, you need to have a staple within . Install New Box. Hold your new, larger box level and mark the wall with a pencil. Cut the drywall to enlarge the hole, staying inside your new lines. The box should be snug. You can always make the hole bigger, never smaller. Feed the cables through the built-in cable clamps and insert the box into the hole.

Nothing is more dangerous and aggravating than loose wires in a junction box. In this video you'll learn how to wire junction boxes correctly. You'll also se.Electric Pro AcademyHow to install a new work electrical box and the correct way to run a new wire to the box. Including how to correctly secure the wire wit.

pushing wires into outlet box

junction box installation instructions

Sheet metal screws come in various lengths, grades, drive types, thread types and materials (such as stainless steel). Uses of sheet metal screws include sealing panels, attaching hinges to cabinets and mounting decorative fixtures.

fitting wires into electrical box|pushing wires into outlet box