what size mig wire for sheet metal The most common sizes for welding on sheet metal are 0.35 and 0.45. MIG Wire selection chart – See full-size version here. Wire Quantity. In making a MIG wire purchase, . We specialize in HVAC repair, AC repair, furnace repair, AC installation, heating repair, sheet metal, and water heater repair in Walnut Creek, CA.

0 · welding wire diameter chart

1 · welding thickness chart

2 · welding mig wire size chart

3 · weld wire selection chart

4 · mig wire diameter chart

5 · mig welding wire size selection

6 · mig welding wire size explained

7 · mig welding sheet metal basics

Vintage 1950’s WALTERS MFG. Metal Enamel Kitchen Cabinet W/ Drawer 20”x16” The cabinet is in good condition considering its age. The top is nearly perfect, but there are a few scratches .

A MIG wire size chart provides recommended wire diameters for different metal thicknesses. Standard sizes range from 0.023 to 0.045 inches for welding various metal gauges. Selecting the appropriate MIG wire size is crucial for successful welding.

difference between handy box and a regular metal box

The most common sizes for welding on sheet metal are 0.35 and 0.45. MIG Wire selection chart – See full-size version here. Wire Quantity. In making a MIG wire purchase, . The selection of the correct MIG welding wire size comes down to your project’s specifics – the material thickness and joint design. As a seasoned welder, I’ve found that a larger wire size is often more suitable for thicker . Using 0.023, 0.024, and 0.030 in MIG solid wires for sheet metal is best. Also, avoid a 100% CO2 shielding gas because it amplifies penetration, which leads to burn-through. The best shielding gas for MIG welding thin mild .

welding wire diameter chart

The choice between 0.8 mm and 0.9 mm MIG wire depends on the thickness of the metal being welded. 0.8 mm wire is suitable for welding thin metal sheets up to 3 mm thick, while 0.9 mm wire is better suited for thicker metals . It’s recommended to use a .023- or .024-inch wire for most light gauge sheet metal work. When the material is 18-gauge and thicker, you may be able to use a .030-inch wire. To weld mild steel, choose an American Welding .

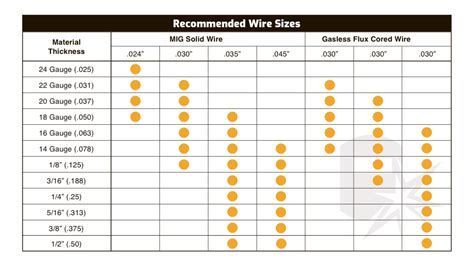

This chart is a helpful guide for choosing the correct wire size and type (solid or flux) of wire based on the thickness of the material being welded. For example, when welding sheet metal, the most common wire sizes are 0.35 and 0.45 inches. However, when welding thin steel, you’ll probably need a solid MIG wire with a smaller diameter, either 0.24 or 0.30 inches. I have an older Miller 180 mig that works great..just wondering if anyone out there can recommend a good wire diameter (.023 or .030) for what I'm doing. Need to step down from my big spool of .035. BTW: Miller recommends ER70S-6 over ER70S-3 wire for dirty/rusty metal, what do you think? Thanks as usual!There seems to be much difference of opinions on which size wire works best on sheet metal (22 g- 18 g) I've always used .030 in my MM210, harris 20 gauge in my 110 machine. I was wondering what others opinions/results were with .023 or .030. . Great 240V small Mig Hobart Handler 140 - Great 120V Mig Hobart Handler EZ125 - IMO the best 120V .

welding thickness chart

welding mig wire size chart

I am about to start a new project using 16 gauge sheet metal and all I have for wire at the moment is .030. Would a smaller wire be better and if so how much better will it be and why. Also is there a difference in using .023 vs.025. I have a lincoln pro mig 180 and it states it can use .025 but I see .023 is a more popular wire size.

Welding sheet metal with Mig wire requires you to consider the following essential factors. Use a Correct Mig Wire Size for Different Gauge Sheet Metal; If you are welding light gauge sheet metal, a .023- or .024-inch wire is the best option. But if the gauge sheet metal is slightly thicker, you can use a .030-inch Mig wire. Higher Argon Gas .

MIG wire sizes typically range from 0.023 to 0.045 inches, and selecting the appropriate size depends on the metal thickness being welded. The wire acts as the filler material that melts and joins metal pieces together during welding. Choosing the right MIG welding wire size is very important for a strong and lasting weld. The size of the wire controls how much .

As is always the case in MIG welding, it is critically important to match the wire type to the base metal. So if you are welding an aluminum base metal, you will need to go with an aluminum wire. . Choose a MIG Wire Size Suitable for Car Panels. The three most common wire sizes in MIG welding are 0.035″, 0.030″, and 0.023″. Of these . A hands on look at the two MIG welding wire sizes that I would recommend for most people.****Affordable self-paced welding courses taught by me****https://co. 0.6 mm sheet metal (car-stuff e.g.) you can only use 0.6 mm. wire, because when using 0.8 wire the heat needed for melting the wire would have melted/blown holes in the sheet. At first glance, this sounds logical, but is it true? And in this situation, a welder-setting of ~23 Amps would be needed (according to the rule: What is .045 MIG wire used for? 0.045 inch (1.2 mm) MIG wire is typically used for welding thicker materials, such as structural steel and heavy fabrication. What size MIG wire is best for sheet metal? For sheet metal, use a smaller wire size like 0.023-0.030 inch (0.6-0.8 mm) for better control and less heat input.

Yep. C25 is 25% carbon dioxide, 75% argon which is the correct mixture for welding steel. Lighter wire for the sheet metal and heavier for the thicker metal (duh). If you're new at welding, use scrap to test it on. Wire speed and amps are key on the mig - too much wire and too little amps will give you a lot of splatter and not much bond.In this video I share with you some awesome mig wire I found for sheet metal. This welding wire is great for rust repair and any sheet metal work. This wire .

In doing some research about MIG welding sheet metal, I've noticed some folks recommend using .023 wire for vehicle applications of 16g - 20g sheet. I'm trying to understand the differences between .023 and .025 as it relates to the wire itself, tips, and drive roll. - . Once clamped, the panels are tack welded together, spacing the tacks no more than 1 inch apart. Every welder has their own preferences for sheet metal. I’m using 0.023-inch ER 70 S-6 filler wire and 15 cfh (cubic feet per hour) of C-25 shielding gas with my Millermatic® 211 MIG welder. After the first tacks are in place, the clamps are removed.

You can do a couple of things to combat this extra heat, the first of which is picking the right wire size. In general, don’t use a wire that is thicker than your sheet metal. If you’re welding 1mm thick steel sheet metal, then you’ll want to use an 0.6mm wire for the best results, although 0.8mm would also work. .030 or .035 flux core wire will work on sheet metal! It is larger in diameter than the equivalent volume of mig wire because of the hollow core filled with flux. Still takes the same amount of current to make the same weld even though the nominal wire size of the mig and flux core is different. The .025 mig wire will be fine for sheet metal. One question I have is what polarity are you using? Mig and flux core welding require different polarity connections. mig must have positive electrode polarity, flux core must have negative electrode polarity.

Ensure that you use very thin wires when welding with delicate, thin sheet metal. Metal Thickness (inches) Recommended MIG Wire Size (inches) 0.024: 0.020: 0.030: 0.023: 0.036: 0.025: 0.048: 0.030: 0.060: 0.035: 4. .

weld wire selection chart

When starting to learn auto body sheet metal welding with a MIG welder, you should opt for a shielding gas that has a higher proportion of argon gas. It is better to use instead of a high percentage of CO2. . It is better to avoid using a flux-cored wire when welding sheet metals. It will make the base metal more susceptible to heat. How to . Using 0.023, 0.024, and 0.030 in MIG solid wires for sheet metal is best. Also, avoid a 100% CO2 . Stick welding is not a delicate process but with a proper setup and rod size, you can weld sheet metal with the SMAW . Also, reduce the tungsten, stick electrode, or MIG wire diameter to the lower amperage accordingly. Appearance. Adapting your welding technique to accommodate different positions is essential for maintaining consistency and weld integrity across various sheet metal applications. MIG Welding Sheet Metal Settings. Achieving optimal MIG welding settings for sheet metal hinges on precise control over voltage and wire feed speed. What is the preferred wire size for sheet metal? I have a miller 250 with .030 wire now. It works for sheet metal with the occasional "blow thru". I only do tacks and jump all around. . When welding sheet metal with mig, don't try to weld continuous beads - instead use multiple tacks - weld a few tacks over the length of a seam, then go back .

The best size MIG wire for car panels depends on the thickness of the panels. Thinner panels usually require smaller wire sizes, such as 0.023-inch or 0.030-inch wire, while thicker panels may require larger wire sizes, such as 0.035-inch or 0.045-inch wire.

When it comes to wire selection for the MIG the rule of the thump is to avoid using filler metal that is thicker than the base metal. Most of the light gauge sheet metal work will require the use of .023- or .24- inch while if you have a sheet metal having a gauge of more than 18-gauge then a .030-inch wire would be the most ideal.The most crucial parameters include voltage, amperage, and wire speed. The challenge of choosing the correct parameters is that they depend on the thickness of weld metal, wire size, type of metal, joint configuration, welding position, or shielding gas. So there is no universal approach to MIG welding thin metal, but there is a solution.This chart is a helpful guide for choosing the correct wire size and type (solid or flux) of wire based on the thickness of the material being welded. All Categories. Welding . WIRE SIZE CHART. RECOMMENDED WIRE SIZES. MIG SOLID WIRE: GASLESS FLUX-CORED WIRE: MATERIAL THICKNESS.024".030".035".045".030".035".045" 24 Gauge (.025) X: 22 Gauge .

The wire ran on for a split second after turning off the arc closing the gap and feeding the wire into the hot weld pool. Designed and 3D printed a brake for the spool which basically fixed it. But for the hours I put into making a half decent one I could have bought a much better unit. I have started playing around with wire size on my new mig as well. I asked the shop that did the work on my car what size wire they use for sheet metal and they use .030 for everything and having been doing it that way for decades. . You certainly CAN use .030", that doesn't make it the proper choice for 18 gauge sheet metal. Just look at .

mig wire diameter chart

$26.99

what size mig wire for sheet metal|welding wire diameter chart