reference point in cnc machine Reference points serve as the starting or zero positions for CNC machine operations. They play a vital role in defining the machine's coordinate system, allowing for accurate positioning and . A trench box is a safety device used to protect workers in trenches. It is a square structure made up of pre-constructed side sheets and adjustable cross members. It is usually made of steel or aluminum.

0 · unity cnc reference point

1 · setting a reference point in cnc

2 · reference point in cnc

3 · cnc reference hole value

4 · cnc reference hole

5 · cnc mdi mode

When people ask if a double tapped breaker is illegal, we assume they refer to electrical codes. Double tapped breakers are against national electrical codes and manufacturer guidelines unless the circuit breaker is rated explicitly for two poles. Electrical updates . See more

The reference point is a fixed point inside the cnc machine whose values are already stored in the cnc machine. So when we take the cnc machine to the reference point those values automatically get active and the cnc machine .Reference points serve as the starting or zero positions for CNC machine operations. They play a vital role in defining the machine's coordinate system, allowing for accurate positioning and .

cnc manufacturer uk

Setting a reference point in CNC is a crucial step to ensure precision, accuracy, and repeatability in machining operations. By following the steps outlined above, operators can set and verify the reference point . The reference point of a CNC machine tool is a fixed position point used for detecting and controlling the movement of the machine tool. The position of the machine tool reference point is precisely adjusted by the . Reference point of any CNC machine has been selected at a specific fixed point during the initial machine design, by the machine design engineers. It is a fixed point, located within machine travel limits, and its actual .

Machine reference point. Every CNC machine has its own origin point or Home location that will serve as the machine’s coordinate system’s origin. The machine reference point is a known point for the CNC machine. You .

cnc manufacturing inc coatesville pa

The machine reference point is a reference point on a CNC controlled machine. In contrast to the workpiece reference point, the machine reference point is a fixed point as base for the complete. The home position, also known as the zero position or reference point, is a specific location within the CNC machine's workspace that serves as a starting point for all machining .Machine reference point (origin) At the heart of the coordinate system lies the machine reference point, often referred to as the origin. This point is the cornerstone of spatial reference within the machining environment, . HiI am Aman welcome to our youtube channel CAD PLUS CAM.About this video:-Friend in this video we will learn about CNC Machine Reference Point || Machine zer.

cnc manufacturing robots

Zero reference point for Grinding Machine WASINO GLS 130 AS; Need help adjusting machine Z reference point! Newbie-NCSTUDIO V10. "back to reference point" (machine keep running until when?) ASAP Need help with machine reference point CTX alpha 300 Heidenhein; Need Help!-Deco 10 swiss screw machine. return to reference point alarm 224 S1 .

224 - RETURN TO REFERENCE POINT. Alarm Description. . CNC Programmers, CNC hobby and DIY CNC guys. Learn how to troubleshoot CNC alarms and find answers for machine problems. Need Help? Can't find the answer? Ask others by posting in the CNC Professional Forum. CNC Control OEM's. GE Fanuc MitsubishiCNC Milling Fundamentals Cartesian Graph for CNCCartesian Graph for CNC Assume the 3-D frame of reference Reference Point (i.e., Origin): (X0, Y0, Z0) Ideally, the tool can move in any of the quadrants Coordinate at any time is designated in one of two ways: Absolute Coordinate System: Calculate the distance relative to the origin (X0, Y0, Z0)※ Stop moving the machine at a point less than half of the ball screw pitch. 8) Select the reference point mode and use the "+" button to return the axis to the reference point. Then, the Z-axis reference point indicator will turn on. (Parameter No. 1815 #4 Z2 = “0” “1”) I am trying to edit our F360 post processor to output G-code files for our Fanuc 3M equipped milling machine. Near the beginning of each program I would like the machine to perform a reference point return followed by setting my work shift offset. We did this on a recent lathe project and the.

What is reference point read CNC Zero Return or Reference Point Return. During G28 reference point return command machine, first reaches intermediate-point rapidly (G00), then it moves rapidly to reference-point position. Programming G28 X(U) Z(W) X, Z absolute intermediate point position. U, W incremental intermediate point position. Examples

The home position serves as a reference point for the machine's coordinate system. Establishing Workpiece Zero: Once the machine is homed, the next step is to establish workpiece zero. . Setting the zero point on a CNC lathe is a crucial step in ensuring accurate and precise machining operations. However, there are several common mistakes .

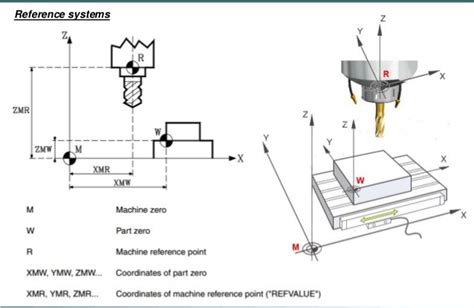

The topic of the micro-teaching is the reference points of CNC machines Presentation and brief description of the reference points on CNC machines, their designations and signs. Mikrotanítás témája a CNC gépek referencia pontjai A CNC gépeken található referenciapontok bemutatása, rövid leírása, jelölésük és jeleik.The main difference between a CNC milling machine and a CNC milling center is the? A. Power knee B. Power quill C. Automatic tool charger D. MCU E. Programmable Z-axis. C. Automatic tool charger. 1 / 27. . Absolute point B. Reference point C. Beginning point D. Point of origin E. Both c and d F. None of the above

unity cnc reference point

setting a reference point in cnc

CNC machine tools tend to build their coordinate systems according to the categories of returning reference points. Due to their detecting structures and principles, four distinct styles of . In the first post in this CNC Router Skills series on Origin Points, I emphasized how critical reference positions are for digital woodworkers. When you’re working on a drawing in CAD, the origin.

The home position, also known as the zero position or reference point, is a specific location within the CNC machine's workspace that serves as a starting point for all machining operations. It is typically set at the extreme end of each axis, ensuring consistent and repeatable positioning. 2. Locating the Home Position. To set the home .

reference point in cnc

Absolute encoders are standard on even commodity grade machine tools now. I’m sure that CTX has them from the age of the machine model. That being said, if you’re not sure wether the machine has absolute encoders or not, reference returning to be sure takes less time that whatever alignment would need to be done after a crash. Reference point (R): Before commissioning, a CNC machine tool must be initialized. This operation consists of moving the carriages towards a point defined by electric stops: this is the machine reference point (R) or Machine Home. This is a non-modifiable point fixed by the machine manufacturer. This is defined by limit switches. Cnc machine report - Download as a PDF or view online for free. Submit Search. . Origin z The stock reference point (origin) is the center of the right face. Origin z indicates the z position of the program origin relative to the .

•tool reference point, f: the starting point of the tool coordinate system the geometric dimension of the tool must be specified relative to this point. these dimensions are called tool correction data. • tool change point: optional, selectable point it must be located in the working space in a place where tool changes can take place smoothly and without collision with the workpiece or .

Fanuc Series 15i 150i Fanuc Alarm OT032 (REFERENCE POSITION RETURN REQUEST) Fanuc Alarm OT032 NEED ZRN (ABS PCDR) Machine absolute position data in the serial pulse coder is lost. How to Home Your CNC Machine - Referencing Tutorial - inar for Siemens 808D CNC ControlThis webinar shows how to Home or reference a CNC lathe or mill co.

It refers to the reference point on a CNC machine where all the coordinates and movements are defined. Understanding machine zero is crucial for achieving precise machining results. In this blog post, we will delve deep into the concept of machine zero, its significance, and the process of setting it up accurately. CNC machine follows the right hand rule. this rule helps with positive axis direction and positive rotation direction. . reference points. Program reference zero- PRZ local reference zero- LRZ machine home reference- M/H. Program . The black steel plate is the mark for the reference point, I only had to bend it a little and slide it a little more in a better position, and the machine finally found the reference mark. The Linear encoder house for the Y-Axis had never been cleaned (for at least 12-16 years) because it is a lot of work to get to it.

By accurately establishing the reference points, CNC machines can consistently locate and position the workpiece, ensuring that each machining operation is performed correctly and with high precision. Types of Machine Datum:\ There are various types of machine datum commonly used in CNC machining, including: 1.

Study with Quizlet and memorize flashcards containing terms like __________ or program zero point is more common as a reference point than using machine coordinates., Machine zero can be located in __________ depending on manufacturer and machine type., Which of the following does the programmer define as the origin of measurements on the workpiece? and more.Search this site. Skip to main content. Skip to navigationSo far, the circuit system of the hydraulic press brake has been fully started, and the Delem DA-53T controller has also started to start and check the system. Wait for a while, the controller enters the system standby state. At this point, we need to check the reference point of the cnc press brake. Perform a reference point check. 1.

cnc mahcining parts factory

cnc manufacturing engineering jobs in va

How is the junction box connected to the solar panel? A PV junction box is attached to the back of the solar panel (TPT) with silicon adhesive. It wires the (usually) 4 connectors together and is the output interface of the solar panel. How to connect the solar panel junction box to the solar array?

reference point in cnc machine|setting a reference point in cnc