sheet metal process ppt This document discusses various sheet metal forming processes including . For example, in one gauge system, 18 gauge steel measures 0.0478 inches thick, but 18 gauge aluminum is 0.0403 inches thick. Because of the varying thicknesses, a gauge chart should be used to ensure the metal meets the required dimensions. The gauge system has long history in metal fabrication.

0 · sheet metal stamping process pdf

1 · sheet metal manufacturing process ppt

2 · sheet metal calculations pdf

3 · sheet metal bending machine ppt

4 · sheet metal basic ppt

5 · sheet metal basic drawing

6 · rolling direction of sheet metal

7 · mechanical properties of sheet metal

DURABLE CONSTRUCTION: The battery box is constructed from 12-gauge steel for the main end frame and bolt brackets, while the 14-gauge base plate provides strength and support for the battery. LONG-LASTING FINISH: The box is zinc-plated to prevent rust and corrosion, ensuring long-lasting durability.

Sheet Metal Forming Sheet metal forming is a process that materials undergo permanent deformation by cold forming to produce a variety of complex three dimensional .The document discusses various sheet metal processes including shearing, .This document discusses various sheet metal processes including cutting, .This document discusses various sheet metal forming processes including .

The document discusses various sheet metal processes including shearing, bending, drawing, and special forming processes. It provides details on: - Common shearing operations like punching, blanking, and notching used to . This document discusses various sheet metal processes including cutting, forming, bending, drawing, and stretching operations. Some key points: 1. Sheet metal work involves forming metal sheets 3-5mm thick into parts .

Sheet metal working involves cutting, bending, drawing, and other forming operations to shape metal sheets. The processes include shearing, blanking, and punching, with various tools like punches and dies. Clearance, .Sheet metal embossing is a stamping process for producing raised or sunken designs or relief in sheet metal. This process can be made by means of matched male and female roller dies, or by passing sheet or a strip of metal between .

The cutting and bending processes are important for manufacturing sheet metal parts for a wide range of applications. The document discusses various sheet metal working processes including cutting operations like shearing, blanking, .3 Sheet metal processing. The raw material for sheet metal manufacturing processes is the output of the rolling process. Typically, sheets of metal are sold as flat, rectangular sheets of standard . This document discusses various sheet metal forming processes including cutting, bending, drawing and other operations. It defines sheet metalworking as including cutting and forming thin sheets of metal between .

Objectives. By the end of today you should be able to. .describe different forming processes, when they might be used, and compare their production rates, costs and environmental . 8. Advantages of Cold Working: o Better surface finish is being obtained. o This process provides higher dimensional accuracy o Widely applied as a forming process for steel. o Thin material can be obtained. o More . 12. Sheet metal parts are usually made by forming material in a cold condition , although many sheet metal parts are in a hot condition because the material when heated has a lower resistance to the deformation. Spring or .

In the manufacturing industry, the sheet metal process is common, and sheet metal parts are used in many different industries, including consumer products, appliances, aircraft, and the automotive and aerospace sectors. . Sheet metal Forming Process - Download as a PDF or view online for free. . • Download as PPT, PDF • 17 likes • 8,969 views. AI-enhanced description. Guhan M Follow. Sheet metal stamping was developed in the 1890s for mass production of bicycles, playing an important role in making interchangeable parts economical. Basic sheet forming .

8. SHEARING • It is a process of cutting a straight line across a strip, sheet • Metal is placed between upper punch & lower die. • Pressure is applied, plastic deformation takes place. • As the pressure is continued, the fracture or crack start at the cutting edge of the punch • As the punch descends further, the small fractures meet & the metal is then sheared.

Sheet Metal Forming - Download as a PDF or view online for free . • Download as PPT, PDF . SHEARING • Shearing is a process for cutting sheet metal to size out of a larger stock such as roll stock. 18. Shearing Machine 19. Shearing • Material thickness ranges from 0.125 mm to 6.35 mm (0.005 to 0.250 in). The dimensional tolerance . Sheet metal working - Download as a PDF or view online for free. Submit Search. . start of process; (2) during process. Note thinning and elongation of walls. Ironing 29. Creates indentations in sheet, such as raised (or indented) lettering or strengthening ribs. Embossing: (a) cross-section of punch and die configuration during pressing; (b . SHEET-METAL FORMING PROCESS Ch # 16. Introduction Shearing Sheet Metal Characteristics Test Methods for Formability of sheet metals Bending sheet and Plate Common Bending Operations Tube Bending and Forming Stretch Forming Deep Drawing. . An Image/Link below is provided (as is) to download presentation Download Policy: Content on the site .

sheet metal stamping process pdf

Presentation on theme: "SHEET METAL process."— Presentation transcript: 1 SHEET METAL process. 2 SHEET METAL FORMING PROCESSES. 3 What is Sheet Metal? A piece of metal whose thickness is between (0.15 mm) and 0.25 inches(6.35 mm). Anything thinner is referred to as a foil and thicker is considered as a plate. .

Group 9 Presentation. Sheet-Metal Forming Processes. Scott Currie Jared Adams Taylor Grisham Yien- Sheng Ao Joe Butner. Extrusion and Drawing of Metals. Definitions. . Sheet metal forming process is carried out in the plane of the sheet by tensile forces with a high ratio of surface area to thickness. The high rate of production and .View Sheet Metal Stamping Process Overview PPTs online, safely and virus-free! Many are downloadable. Learn new and interesting things. Get ideas for your own presentations. . Administrator Created Date: 8/17/2001 7:44:58 PM Document presentation format. Title: FUNDAMENTALS OF METAL FORMING Author: Mikell P. Groover Last modified by . 8. Salient points about rollingSalient points about rolling Rolling is the most extensively used metal formingRolling is the most extensively used metal forming process and its share is roughly 90%process and its share is roughly 90% The material to be rolled is drawn by means of frictionThe material to be rolled is drawn by means of friction into the two revolving .

Sheet metal forming process is carried out in the plane of the sheet by tensile forces with a high ratio of surface area to thickness. The high rate of production and formability is determined by its mechanical properties. . Group 9 Presentation. Sheet-Metal Forming Processes. Scott Currie Jared Adams Taylor Grisham Yien- Sheng Ao Joe Butner .

1) Incremental sheet forming is an innovative metal forming process where a spherical tool is used to push a sheet into a desired shape without the need for dies. 2) The document provides an overview of the incremental sheet forming process, including its history and development, common methods like single-point and two-point forming .Sheet metal forming process Chapter 7 Introduction Sheet metal forming operations produce a wide range of consumer and industrial products, such as metal desks, appliances, aircraft fuselages, car bodies, and kitchen utensils. Sheet-metal forming also called press working, press forming or stamping, is among the most important of metalworking processes, dating back to . 2. Introduction • In laser cutting and drilling, the focused laser beam is directed onto the surface of the work piece to rapidly heat it up, resulting in melting and/or vaporization, depending on the beam intensity and work .Sheet-Metal Parts (a) (b) Figure Examples of sheet-metal parts. (a) Die-formed and cut stamped parts. . Presentation on theme: "Sheet-Metal Forming Processes"— Presentation transcript: . 41 Stretch-Forming Process Sheet metal is clamped along its edges and then stretched over a die or form block, which moves .

3. Shearing : Sheet metal subjected to shear stress developed between a punch and a die is called shearing Fig : (a) Schematic illustration of shearing with a punch and die, indicating some of the process variables. Characteristic features of (b) a punched hole and (c) the slug. Note that the scales of the two figures are different. 10. 10 10 CONFIDENTIAL Metal Stamping manufacturing is the process of creating metal parts by applying extreme pressure to a blank piece on metal and forming the metal into a desired shape Corners should have a minimum radius of 0.5 x material thickness or 0.4 mm (0.016in) whichever is greater. Sharper corners can be produced but at a greater die .

Manufacturing Technology (BPT 4413) • Deep drawing • A process in which sheet metal is stretched into the desired part shape. • A tool pushes downward on the sheet metal, forcing it into a die cavity in the shape of the desired part. • Deep drawn parts are characterized by a depth equal to more than half of the diameter of the part.

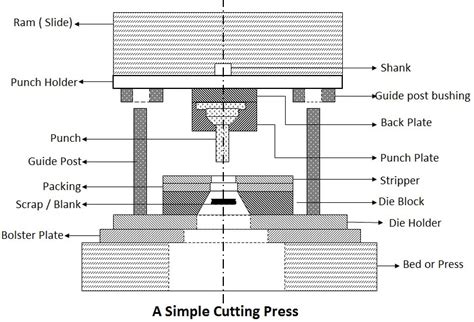

1. Metal forming processes Metal forming: Large set of manufacturing processes in which the material is deformed plastically to take the shape of the die geometry. The tools used for such deformation are called die, punch etc. depending on the type of process. Plastic deformation: Stresses beyond yield strength of the workpiece material is required.Introduction Sheet metal is simply metal formed into thin and flat pieces. It is one of the fundamental forms used in metalworking, and can be cut and bent into a variety of different shapes. Countless everyday objects are constructed of the material. Thicknesses can vary significantly, although extremely thin thicknesses are considered foil or leaf, and pieces thicker .

sheet metal manufacturing process ppt

Group 9 Presentation. Sheet-Metal Forming Processes. Scott Currie Jared Adams Taylor Grisham Yien- Sheng Ao Joe Butner. Extrusion and Drawing of Metals. . Surface Area:Volume is very high for sheet metal process. Plates – thickness > 0.25 inches Boilers, bridges, ships, etc. use relatively thick plates Usually sheet forming is done on .

a metalworking process where sheet metal is pressed between a die and a rubber block, made of polyurethane. Under pressure, the rubber and sheet metal are driven into the die and conform to its shape, forming the part. Rubber pads can have a general purpose shape, like a membrane. Alternatively, they can be machined Metal spinning is a sheet metal forming process that uses rollers to form axisymmetric parts over a rotating mandrel. There are three main types: conventional spinning, shear spinning, and tube spinning. Spinning can be done hot or cold and involves placing a metal blank against a mandrel and using tools to deform the material into shape as it .Metal Forming Processes - Metal forming usually include the process of transformation processes on a metal sheet. Metal sheet is changed into several other forms as sheet, wires, plates etc. Metal sheet forming is done in many metal forming companies in many countries.

Using little more than a sheet of 16-gauge steel and some hand tools, we recreated the floor pans, including the ribs where needed. Material costs were cheap—less .

sheet metal process ppt|mechanical properties of sheet metal