cnc machine electrical drawing In this blog post, we will dive into the intricacies of the CNC machine circuit diagram, exploring its components, their connections, and how they work together to ensure smooth operation. By . Here is a comprehensive guide to help you choose the correct screw size for metal electrical junction boxes: Standard Screw Sizes for Junction Boxes: The most commonly used screw sizes for junction boxes are #6 (3.5mm) and #8 (4mm).

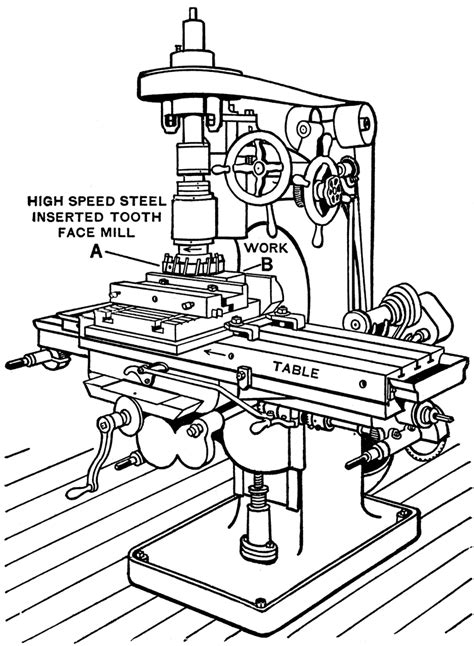

0 · vertical milling machine drawing

1 · machine parts drawing with dimensions

2 · create cnc file from drawing

3 · cnc turning machine drawing

4 · cnc pen plotter circuit diagram

5 · cnc machine drawing pdf

6 · 3d printable cnc machine

7 · 2d drawing and cnc turning

The most common electrical box screw size is 6-32 machine screw. However, for many applications, 6-32 is too light duty, so we use an 8-32 or even a 10-32 instead. The thread pitch, however, is always 32.

A well-designed CNC machine wiring diagram is essential for the successful installation and operation of a CNC machine. It should accurately depict the connections between the various electrical components, ensuring that the .Educate readers on how to read and interpret a CNC machine electrical wiring diagram. Explain the symbols, notations, and color coding commonly used in wiring diagrams. Break down the . A CNC machine wiring diagram is a documented blueprint detailing the electrical connections necessary to power a CNC machine. The diagram typically includes a connection point map with detailed diagrams of the .In this blog post, we will dive into the intricacies of the CNC machine circuit diagram, exploring its components, their connections, and how they work together to ensure smooth operation. By .

In-depth analysis of a real-world CNC machine schematic diagram. Explanation of each component and its function within the machine. At this point, we have covered 700 words.The wiring diagram and circuit design for CNC machines play a crucial role in ensuring their optimal functioning and precision. This article will provide an overview of the key components and considerations when creating a wiring .

CNC electrical diagrams are essential for keeping machinery running properly. They provide an overview of the electrical signals and connections that keep machines in sync and working at optimal levels. A CNC wiring diagram is an essential document that outlines how the machine is wired together. It shows all the connections between components, such as motors, controllers, and drivers. This includes both electrical and .

18.0 cu in brown plastic sylvania electrical box age

cnc control system electrical circuit diagram note: all functions may not be present or available as shown. refer to user manual. 11l1 device symbol . standard mill electrical drawing (yaskawa) .

Topic for Mondays, Wednesdays and Fridays: Microcontroller programming and circuit building. This tutorial will make you an expert in wiring CNC electronics using a parallel breakout board and standard stepping motors and stepping .A well-designed CNC machine wiring diagram is essential for the successful installation and operation of a CNC machine. It should accurately depict the connections between the various electrical components, ensuring that the machine operates smoothly and safely.Educate readers on how to read and interpret a CNC machine electrical wiring diagram. Explain the symbols, notations, and color coding commonly used in wiring diagrams. Break down the different sections of the diagram.

A CNC machine wiring diagram is a documented blueprint detailing the electrical connections necessary to power a CNC machine. The diagram typically includes a connection point map with detailed diagrams of the different cables .

In this blog post, we will dive into the intricacies of the CNC machine circuit diagram, exploring its components, their connections, and how they work together to ensure smooth operation. By the end, you will have a solid understanding of the electrical .In-depth analysis of a real-world CNC machine schematic diagram. Explanation of each component and its function within the machine. At this point, we have covered 700 words.The wiring diagram and circuit design for CNC machines play a crucial role in ensuring their optimal functioning and precision. This article will provide an overview of the key components and considerations when creating a wiring schematic for CNC machines.

CNC electrical diagrams are essential for keeping machinery running properly. They provide an overview of the electrical signals and connections that keep machines in sync and working at optimal levels. A CNC wiring diagram is an essential document that outlines how the machine is wired together. It shows all the connections between components, such as motors, controllers, and drivers. This includes both electrical and electronic components, as well as physical components such as switches and connectors.cnc control system electrical circuit diagram note: all functions may not be present or available as shown. refer to user manual. 11l1 device symbol . standard mill electrical drawing (yaskawa) axis drives and motors. d. es0121. nts. 3. machmotion 14518 cr 7240 rolla, missouri, usa 573-368-7399

Topic for Mondays, Wednesdays and Fridays: Microcontroller programming and circuit building. This tutorial will make you an expert in wiring CNC electronics using a parallel breakout board and standard stepping motors and stepping motor drivers.

A well-designed CNC machine wiring diagram is essential for the successful installation and operation of a CNC machine. It should accurately depict the connections between the various electrical components, ensuring that the machine operates smoothly and safely.Educate readers on how to read and interpret a CNC machine electrical wiring diagram. Explain the symbols, notations, and color coding commonly used in wiring diagrams. Break down the different sections of the diagram.

A CNC machine wiring diagram is a documented blueprint detailing the electrical connections necessary to power a CNC machine. The diagram typically includes a connection point map with detailed diagrams of the different cables .In this blog post, we will dive into the intricacies of the CNC machine circuit diagram, exploring its components, their connections, and how they work together to ensure smooth operation. By the end, you will have a solid understanding of the electrical .

In-depth analysis of a real-world CNC machine schematic diagram. Explanation of each component and its function within the machine. At this point, we have covered 700 words.The wiring diagram and circuit design for CNC machines play a crucial role in ensuring their optimal functioning and precision. This article will provide an overview of the key components and considerations when creating a wiring schematic for CNC machines.

vertical milling machine drawing

CNC electrical diagrams are essential for keeping machinery running properly. They provide an overview of the electrical signals and connections that keep machines in sync and working at optimal levels. A CNC wiring diagram is an essential document that outlines how the machine is wired together. It shows all the connections between components, such as motors, controllers, and drivers. This includes both electrical and electronic components, as well as physical components such as switches and connectors.cnc control system electrical circuit diagram note: all functions may not be present or available as shown. refer to user manual. 11l1 device symbol . standard mill electrical drawing (yaskawa) axis drives and motors. d. es0121. nts. 3. machmotion 14518 cr 7240 rolla, missouri, usa 573-368-7399

19 rack mountable metal box 1u

machine parts drawing with dimensions

create cnc file from drawing

We find multiple types of junction boxes with their properties and advantages. For this reason, we categorize these electrical junction box types based on their features and applications. We will discuss each type in the following section to help you spot the best type for your requirements.

cnc machine electrical drawing|cnc turning machine drawing